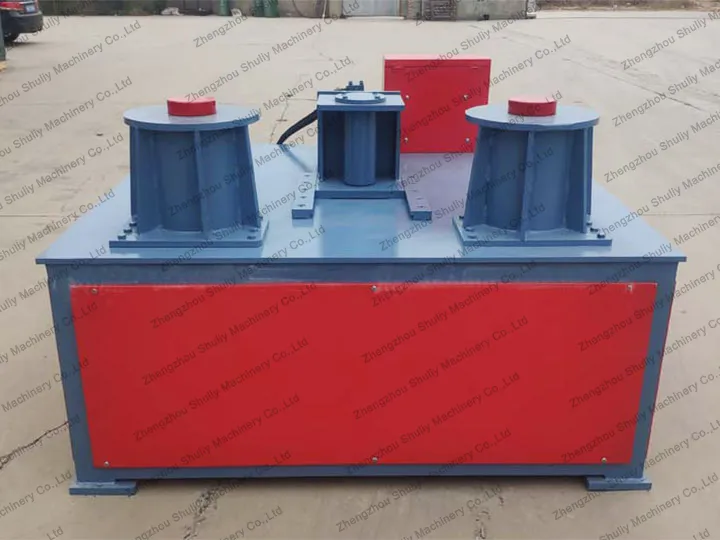

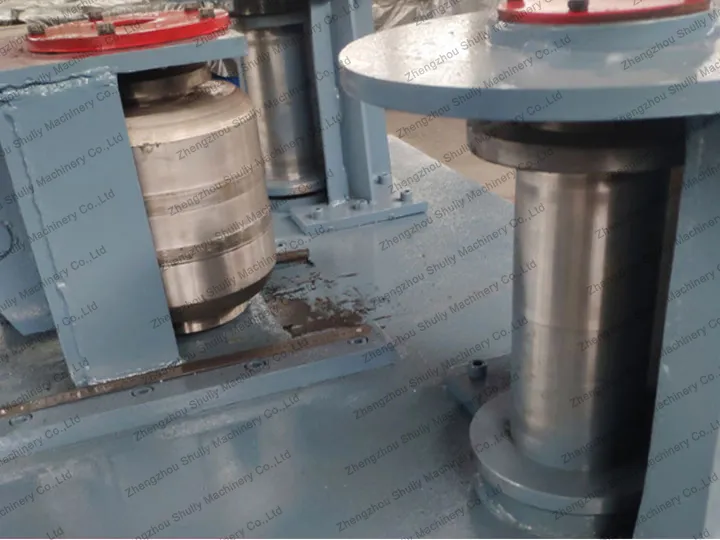

H & I-beam cold bending machine

H Beam Bending Machine | Hydraulic Arch Bending Machine

Processing range: 25# I-beam, 140H steel/14 channel steel, 150 round tube/150 square tube

Total power: 3+3+3kW

Bending radius range: 2m

Hydraulic system pressure: 16MPa

Main drive wheel speed: 7.7r/min

Machine weight: about 1600kg

Overall dimensions: 250*150*80cm

This I-beam cold bending machine is high-efficiency equipment designed for bending I-beam, H-beam, channel steel, round & square tubes, etc., which is widely used in the fields of construction, bridge and steel structure manufacturing.

Molds of this equipment can be customized according to the demand for hydraulic high-power transmission.

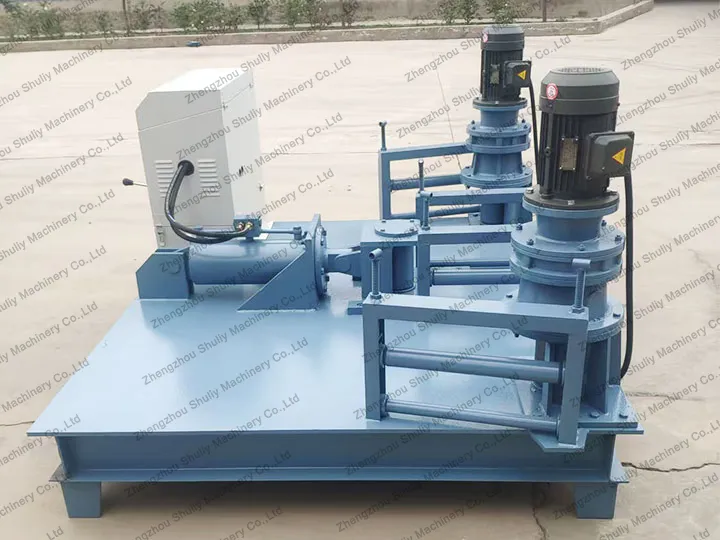

Our automatic arch bending machine for steel I beams is hydraulically driven, with strong bending capacity and precise operating performance, to meet customer demand for high-precision, high-efficiency processing.

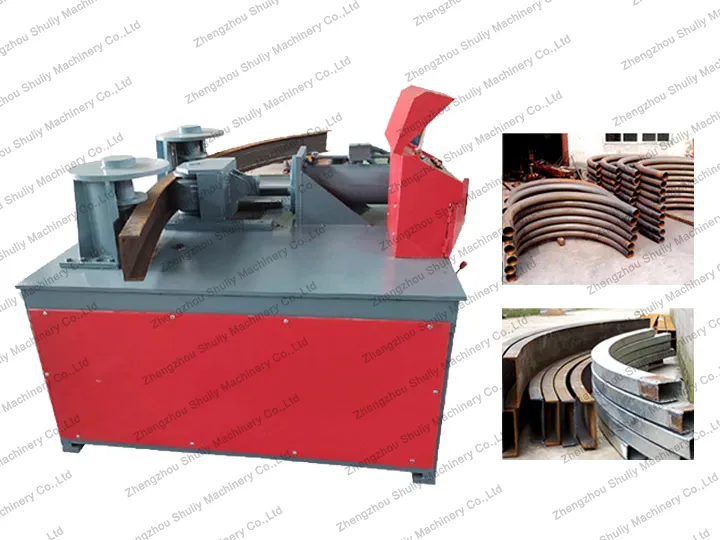

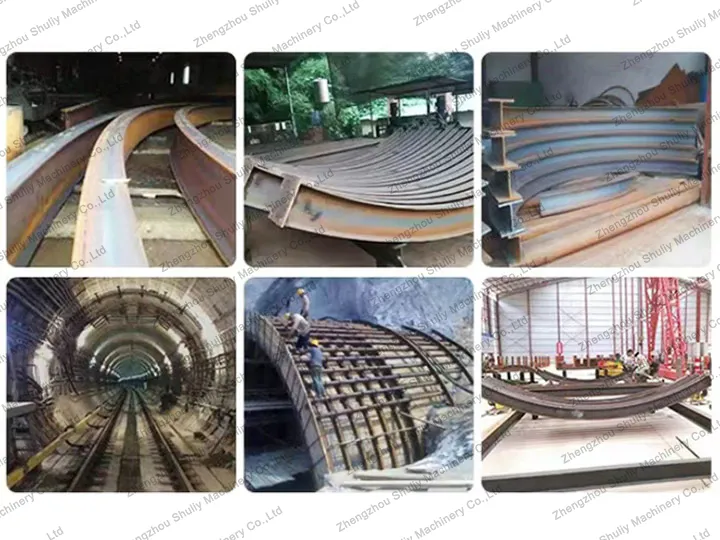

End products of automatic I-beam cold bending machine

Our H beam bending machine can process all kinds of curved, round and specially shaped steel structures. The finished products are different according to customers’ demands and are widely used in projects such as bridges, tunnels, subways, highways, building steel structures, factory beams, billboards and so on. Different steel bending shapes and precision are demonstrated:

Advantages of hydraulic arch bending machine

With its powerful performance and efficient operation, the I-beam cold bending machine has become the preferred equipment for I-beam bending processing, its main advantages include:

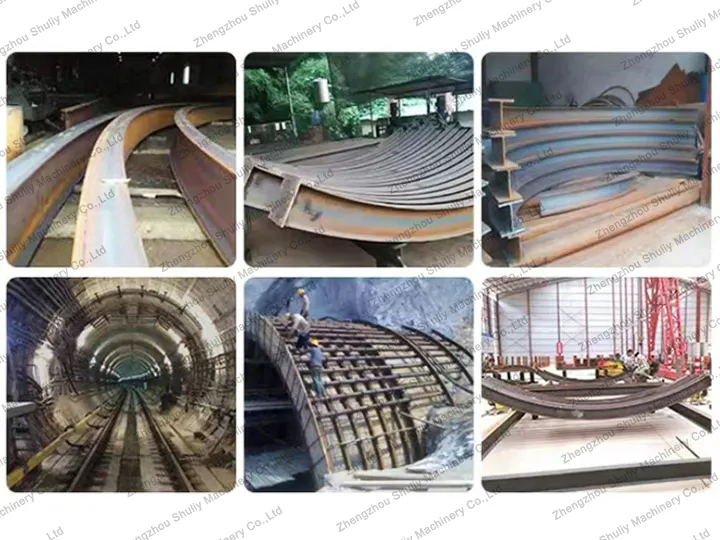

- It works by the hydraulic drive with a powerful bending ability.

- Equipped with an intelligent control system, the I-beam cold bending machine has high-precision control on bending angles.

- There is an adjustable bending radius range of 2m.

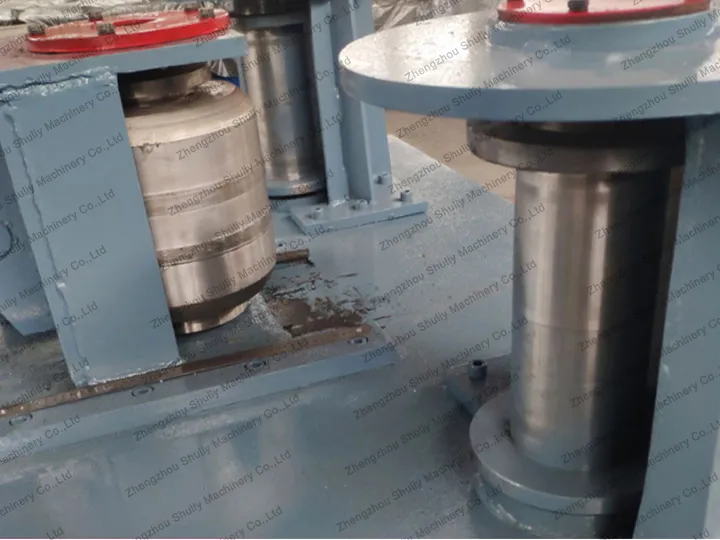

- Using high-quality steel and precision parts, the equipment structure is robust and durable, suitable for large-size and high-strength profile processing.

- The hydraulic system operates stably with low energy consumption, which helps customers to reduce operating costs.

- With humanized design and an intuitive operation interface, even the novice can quickly get started.

- The machine has different bending sections(moulds) to meet diffente steel bending demands.

Technical parameters of H & I-beam cold bending machine

The following parameters are for your reference when you choose equipment. Our parameter information includes adaptable materials, power, machine size, weight and so on.

- Processing range: 25# I-beam, 140H steel/14 channel steel, 150 round tube/150 square tube

- Total power: 3+3+3kW

- Bending radius range: 2m

- Hydraulic system pressure: 16MPa

- Main drive wheel speed: 7.7r/min

- Machine weight: about 1600kg

- Overall dimensions: 250*150*80cm

How about Shuliy I-beam cold bending machine price?

The price of our H/I beam bending machine is affected by the equipment model, hydraulic system configuration, customization requirements, etc.

- Equipment specifications: the larger the processing range and the more powerful the equipment, the higher the price.

- Configuration level: whether it is equipped with a CNC numerical control system, hydraulic system level, etc.

- Customization needs: customized design according to customer’s special needs may increase the cost.

Shuliy always adheres to the principle of high cost performance and provides customers with high-quality equipment and perfect service. If you need a detailed quotation, please contact us and we will provide the most suitable solution according to your needs.

Service about hydraulic I-beam cold bending machine

We not only provide high-quality H beam bending machine, but also support the provision of complete technical support and after-sales service. We ensure that every aspect of the equipment from purchase to use is smooth and worry-free.

- Pre-sales consulting: recommend the right equipment model and configuration according to customer needs.

- Installation and commissioning: before leaving the factory, install and debug the equipment to ensure normal operation.

- Operation training: provide customers with detailed operation training to help operators quickly master the use of equipment.

- After-sales maintenance: provide long-term after-sales support, including regular maintenance, troubleshooting and technical upgrading services.

- Parts supply: ensure the timely supply of original parts to prolong the service life of the equipment.

Our service team is on standby 24 hours a day to solve problems for customers and ensure that the equipment is always in the best condition.

As a professional manufacturer of rebar handling equipment, we also have steel bar straightening machine, tube bending machine and hoop bending machine for you to choose. For more details or to get the latest quotation, please feel free to contact us to benefit your rebar processing business!