ایک اچھا میٹل بیلر مشین مینوفیکچرر کا انتخاب کیسے کریں؟

موثر سکریپ میٹل بیلر مشین ہر قسم کے سکریپ میٹل، کین، سکریپ آئرن اور دیگر قسم کے دھاتی فضلہ کو مربع بلاکس میں دبا سکتی ہے۔ خودکار میٹل بیلر مشین سکریپ میٹل ری سائیکلنگ مارکیٹ کا ضروری سامان ہے، بہت سے سکریپ ری سائیکلنگ اسٹیشنز، اور میٹل پروسیسنگ انٹرپرائزز کو اس قسم کی بیلنگ مشین خریدنے کی ضرورت ہے، تو ایک اچھی میٹل بیلنگ مشین مینوفیکچررز کا انتخاب کیسے کریں؟

دھاتی بیلر استعمال کرنے کا کیا مطلب ہے؟

کمرشل آئرن شیٹس بیلنگ مشین نہ صرف اسکریپ میٹل اسٹوریج کا مسئلہ حل کر سکتی ہے بلکہ دھات کے وسائل کو بھی بچا سکتی ہے اور اسکریپ میٹل کی فروخت کی قیمت میں اضافہ کر سکتی ہے۔ اس کے علاوہ، دھاتی بیلر کے بیلنگ کے افعال کی وجہ سے، زمین میں کم فضلہ دھاتی سکریپ ہوں گے، جس سے زیادہ زمین پر قبضہ کم ہوسکتا ہے اور دھاتی فضلہ کو کم کیا جاسکتا ہے۔

دھاتی بیلنگ مشین کی اہم ایپلی کیشنز

میٹل بیلنگ مشین اسٹیل ملز، فاؤنڈریز، سکریپ اسٹیل، اور سکریپ آئرن ری سائیکلنگ پروسیسنگ انٹرپرائزز اور الوہ دھاتی پیداواری پلانٹس کے لیے موزوں ہے۔ میٹل بیلنگ مشین کو پورے کمپریشن کے عمل کے دوران گرم کرنے اور متعلقہ اضافی اشیاء شامل کرنے کی ضرورت نہیں ہے، جس سے ترسیل، ورزش کی لاگت کم ہوتی ہے اور بھٹی کی رفتار بہتر ہوتی ہے۔

نئی قسم کی سکریپ میٹل پریس مشین مختلف دھاتی اسکریپ، اسٹیل شیونگ، اسکریپ اسٹیل، ویسٹ ایلومینیم، اسکریپ کاپر وغیرہ کو کیوبک، مربع، مسدس یا بیلناکار بلاکس میں ایڈجسٹ ہائیڈرولک پریشر کے تحت نکال سکتی ہے۔

ہائیڈرولک سکریپ دھاتی بیلر فوائد

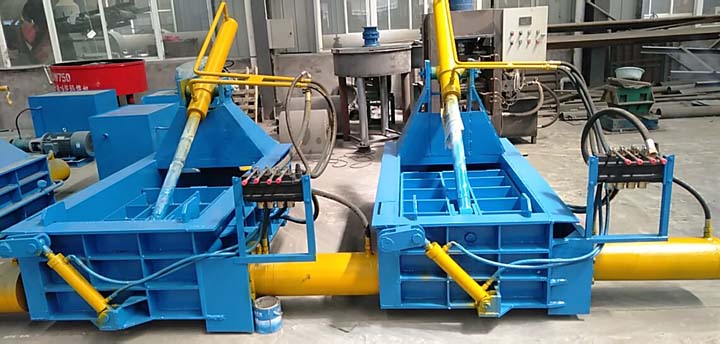

1. ہائیڈرولک ڈرائیو (یا ڈیزل ڈرائیو) سکریپ میٹل بیلر کے تمام ماڈلز کے لیے منتخب کی گئی ہے۔

2. سکریپ میٹل شیٹس بیلر مشین کا ڈسچارج موڈ مختلف ہو سکتا ہے، جیسے موڑنا، دھکا دینا یا دستی چننا۔

3. دھاتی سکریپ بیلر کی ساخت کمپیکٹ ہے، اور اسے انسٹال کرتے وقت پاؤں کو ٹھیک کرنے کی ضرورت نہیں ہے۔ جہاں بجلی کی فراہمی نہیں ہے، ڈیزل انجن کو اس لوہے کی بیلنگ مشین کے لیے پاور کے طور پر استعمال کیا جا سکتا ہے۔