Kishikio cha Chuma chakavu cha Viwanda kwa Usafishaji wa Metali

Metal Crusher | Viwanda Metal Shredder

Chapa ya mashine: Shuliy

Mfano: SL-400, SL-600, SL-800, SL-1000, SL-1200, nk.

Motor yenye vifaa: kila shredder ina motors mbili za umeme na reducers mbili.

Manufaa: kazi zote za kusudi, programu pana na mifano mbalimbali.

Huduma: ubinafsishaji, huduma za baada ya mauzo, nk.

Shuliy scrap metal shredder, also called twin-shaft shredder, crushes various waste metals like steel, iron, aluminum, etc. into small pieces for recycling. This industrial metal shredder is multi-functional equipment, suitable for wastes with different hardness, shapes, and sizes.

Nyenzo za mwisho ziko katika vipande vidogo, ambavyo vinaokoa nafasi, rahisi kwa usafirishaji na kuchakata tena.

Mashine hii ya kupasua chuma ina sifa ya ufanisi mkubwa wa kusagwa, kelele ya chini, matumizi ya chini ya nishati, na pato la juu. Inajumuisha faida za kasi ya chini na muundo wa juu wa shear torque.

Pamoja na kuongezeka kwa tasnia ya kuchakata taka, mashine ya kusaga chuma yenye shimo mbili imekuwa ikitumika zaidi na zaidi katika tasnia mbalimbali za kuchakata. Ikiwa una nia, karibu kuwasiliana nasi!

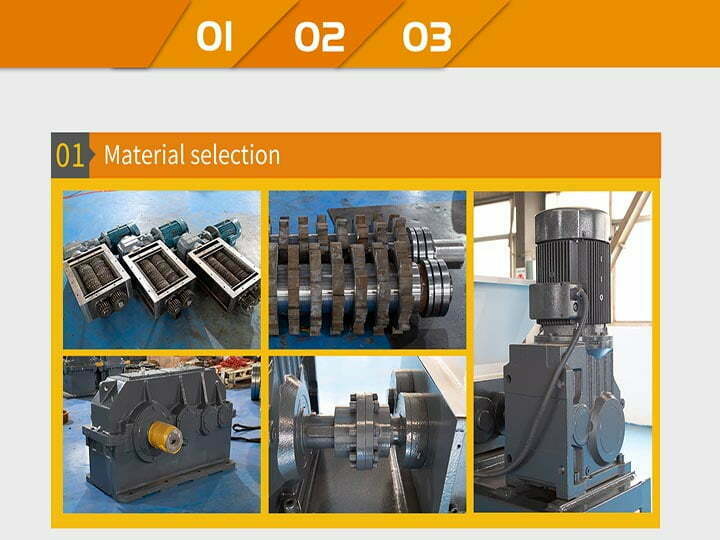

Mambo muhimu ya shredder ya viwanda ya chuma

- Mbalimbali ya maombi. Kipasua chakavu cha chuma kinaweza kutumika kurarua vyuma chakavu na chuma chakavu, alumini chakavu, wasifu wa alumini, n.k.

- Pia, inaweza kuponda bodi za mzunguko, vipengele vya chujio vya mafuta ya injini, vifaa vya umeme, ngozi, mbao, plastiki, mifupa na vifaa vingine.

- Blade iliyotengenezwa na 9CrSi. 9CrSi hutumika mahususi kwa vile vile vya kusagwa chuma. Blade hii ina shredding kali na uwezo wa juu wa kusagwa.

- Kipunguza kasi cha chini cha gia. Kwa sababu ya kipunguzaji hiki, mashine ya kukagua chuma chakavu ya Shuliy ina ufanisi wa juu wa upitishaji, utendakazi thabiti na kelele ya chini.

- Torque kubwa. Mashine hii ya kuponda chuma inafaa kwa vifaa vya ujazo anuwai, haswa vifaa vya taka vilivyo na idadi kubwa na maumbo yasiyo ya kawaida.

- Uendeshaji rahisi. Ukiwa na baraza la mawaziri la kudhibiti nguvu tofauti, unahitaji tu kuendesha baraza la mawaziri la kudhibiti nguvu.

- Kubinafsisha. Kulingana na mahitaji tofauti, tunaweza kuandaa mashine na fremu, jukwaa la kufanya kazi, conveyor (ya kulisha au kutoa), nk.

Vigezo vya kiufundi vya crusher ya chuma chakavu kwa ajili ya kuuza

Kuna data kuu ya kiufundi ya mifano yetu ya shredder chakavu ya chuma. Mifano mbalimbali zinapatikana kwa kumbukumbu yako.

| Mfano | SL-400 | SL-600 | SL-800 | SL-1000 | SL-1200 | SL-1600 | SL-1800 | SL-2000 |

| Vifaa vya sahani ya blade | 9CrSi | 9CrSi | 9CrSi aloi ya chuma | 9CrSi | 9CrSi | 9CrSi | 9CrSi | 9CrSi |

| Sahani ya blade.(mm) | 200 | 245 | 300 | 400 | 400 | 450 | 500 | 550 |

| Unene wa sahani (mm) | 20 | 20 | 40-50 | 30 | 30 | 40 | 50 | 100 |

| Idadi ya blade (pcs) | 12 | 15 | 18 | 18 | 15 | 15 | 15 | 15 |

| Kiasi cha sahani ya blade (pcs) | 20 | 25 | 40 | 33 | 40 | 40 | 36 | 20 |

| Ukubwa(m) | 2.5*1.5*1.9 | 3.5*1.5*1.9 | 3.8*1.5*1.9 | 4.3*1.6*1.8 | 4.5*1.6*1.8 | 5.2*1.8*1.9 | 5.5*1.9*2.1 | 5.7*2*2.1 |

| Uzito(t) | 1 | 3 | 4 | 6 | 7 | 12 | 16 | 22 |

| Nguvu (k) | 11 | 15 * 2 pcs | 18.5 * 2 pcs | 30 * 2 pcs | pcs 37*2 | 45 * 2 pcs | 55 * 2 pcs | 75 * 2 pcs |

Notes to mini scrap metal shredder:

- Motors zote ni motors safi za kitaifa za shaba.

- Vipunguzi huchukua aina ya kitaifa ya uzani.

Muundo wa shredder ya chuma chakavu cha mini

Muundo mkuu wa mashine ya kukaushia vyuma chakavu ni pamoja na hopa ya kulisha, fremu, mori ya gia, gari la umeme, ngazi, uzio wa kinga, puli, kifuniko cha kinga, na mlango wa kutolea maji. Ifuatayo ni habari maalum.

- Ukubwa wa hopper ya kulisha ni 60mm * 60mm.

- Saizi ya hopper inaweza kubinafsishwa kulingana na mahitaji maalum.

- Motors mbili zina vifaa vya kupunguza gear mbili, kuhakikisha kazi imara na kuepuka kelele.

- Kifuniko cha kinga kwenye pulley kinaweza kuwa na jukumu la kuzuia vumbi na ulinzi wa usalama.

- Reli za walinzi na ngazi ni rahisi kwa wafanyikazi kutazama na kuhakikisha usalama.

- Vipande vya kuponda chuma vya Shuliy vinatengenezwa kwa nyenzo za juu-nguvu na zinazostahimili kuvaa.

- Tunatoa blade zenye ugumu tofauti kwa uteuzi ili kukidhi mahitaji tofauti.

- Viumbe hupitisha makucha mengi na miundo mingine ili kuhakikisha kwamba makucha yanaweza kufunga nyenzo za taka kwa nguvu wakati wa kuzirarua.

Kanuni ya kazi ya crusher ya chuma

Kanuni ya kazi ya mashine ya kupasua chuma inategemea hasa mfumo wake wa ndani wa mihimili miwili ya kukata ili kukamilisha mchakato wa kupasua taka za chuma. Ifuatayo ni kanuni yake maalum ya kufanya kazi:

- Kulisha: kwanza, chakavu cha chuma cha kusindika huingizwa kwenye shredder kupitia bandari ya kulisha.

- Kulisha kunaweza kufanywa kwa mikono au kupitia mfumo wa kusambaza kiotomatiki.

- Kukata shimoni mara mbili: sehemu ya msingi ya shredder ya chuma chakavu ni shafts mbili za kisu zinazozunguka zilizopangwa kwa sambamba.

- Kila shimoni ina vifaa vya seti nyingi za visu za alloy za juu, ambazo zimepangwa kwa utaratibu fulani na pembe.

- Wakati shredder inapoanzishwa, shafts hizi mbili za visu zitazunguka kwa mwelekeo tofauti.

- Kunyoa na kupasua: wakati chakavu cha chuma kinalishwa kati ya visu vya visu, vile vinavyozunguka vitazalisha nguvu kali za kukata na kubomoa kwenye chakavu, na kuivunja vipande vidogo.

- Kwa kuwa mwelekeo unaozunguka wa shafts ya visu ni jamaa, inaweza kwa ufanisi kurarua chakavu cha chuma katika pembe nyingi na maelekezo.

- Utekelezaji: vipande vya chuma vilivyopigwa hutolewa kupitia bandari ya kutokwa chini ya shredder.

- Ikiwa ni lazima, bandari ya kutolewa inaweza kushikamana na ukanda wa conveyor au kifaa kingine cha usafiri ili kusafirisha vipande kwenye eneo lililowekwa.

Chakavu kinachotumika cha mashine ya kukagua vyuma chakavu vya viwandani

Mashine yetu ya chuma ya viwandani inaweza kutumika kurarua mabaki mbalimbali. Tunaorodhesha malighafi zifuatazo kwa marejeleo yako.

- Metali zenye feri

- Karatasi ya chuma: ikiwa ni pamoja na karatasi za chuma za kupima nyembamba na paa za bati na sidings, nk.

- Stamping: chakavu zinazozalishwa katika uzalishaji mbalimbali stamping.

- Chips: chips zinazozalishwa wakati wa usindikaji wa chuma.

- Sehemu zilizoumbwa: sehemu mbalimbali za chuma zilizopigwa.

- Vifaa vya nyumbani: taka vifaa vya nyumbani.

- Paneli za gari: pamoja na paneli za gari lakini sio makombora ya gari zima.

- Aloi ya alumini: bidhaa mbalimbali za aloi za aluminium taka.

- UBC iliyopakiwa: makopo ya alumini ya taka yaliyopakiwa.

- Metali zisizo na feri

- Copper: bidhaa mbalimbali za shaba za taka.

- Shaba: ikiwa ni pamoja na sehemu za shaba za taka na anode za shaba.

- Karatasi za alumini na extrusions: taka karatasi za alumini na extrusions.

- Mabomba ya shaba: mabomba ya shaba ya taka.

- Radiators: radiators taka.

- Waya na sahani zilizofunikwa na fedha: waya na sahani za fedha.

- Magurudumu ya alumini: magurudumu ya alumini chakavu.

- Vipu vya alumini na coils: coils chakavu alumini na coils.

- Mpira na plastiki

- Matairi ya mpira: taka za matairi ya gari, kama matairi ya gari, matairi ya lori, nk.

- Plastiki: chupa mbalimbali za plastiki zilizotupwa, mabomba ya plastiki, filamu za plastiki, nk.

- Mbao na kadibodi

- Mbao: aina mbalimbali za mbao zilizotupwa, kama pallets za mbao.

- Kadibodi: kadibodi ya taka, kadibodi ya bati, nk.

- Kaya na nguo

- Samani za taka: pamoja na kuni zilizotupwa na samani za chuma.

- Nguo kubwa: kama vile vitambaa vilivyotupwa na nguo.

- Elektroniki na vifaa

- Sehemu za umeme: sehemu za umeme zilizotupwa na vifaa, nyaya za taka, nk.

- Chakavu cha elektroniki: taka za bodi za mzunguko wa elektroniki.

- Ngoma za mafuta na makopo

- Nyenzo zingine ambazo ni ngumu kushughulikia

- Wanyama wakubwa: kama vile mifugo wakubwa waliokufa.

- Mabomba makubwa: chuma chakavu au mabomba ya plastiki.

Vipi kuhusu bei ya mashine ya kuchana chuma chakavu?

Bei ya mashine ya kuponda vyuma chakavu huathiriwa na mambo kadhaa, kama vile modeli za mashine, uwezo, modeli ya mori ya kupunguza kasi na injini.

Ikiwa unataka kujua bei halisi ya mashine ya kupasua shimoni pacha, tafadhali wasiliana nasi! Tuambie mahitaji yako, tutakupa suluhisho linalofaa zaidi kwa mahitaji yako.

Kwa nini uchague Shuliy kama muuzaji wa mashine ya kunyoa chuma chakavu?

Tunajulikana sana katika tasnia ya kuchakata chuma chakavu kwa sababu ya faida zifuatazo.

- Usaidizi wa kiufundi

- Mashauriano ya kabla ya kuuza

- Mafunzo ya ufungaji na uendeshaji kwenye tovuti

- Huduma ya baada ya mauzo

- Huduma za ukarabati na matengenezo ndani ya kipindi cha udhamini

- Huduma za uingizwaji wa sehemu za kuvaa

- Usaidizi wa matengenezo ya muda mrefu na huduma za uboreshaji wa kiufundi zaidi ya kipindi cha udhamini

- Huduma iliyobinafsishwa

- Kubuni na kuzalisha mifano iliyoboreshwa kulingana na mahitaji yako maalum

- Ugavi wa vipuri

- Ugavi wa wakati wa vipuri vya awali vya shredder ndogo ya chuma chakavu

Vifaa vingine vya kuchakata chuma: shears za chuma

We also have the hydraulic metal cutting machine available for metal recycling, like alligator shear, gantry shear, etc., with specific reference to the following:

Wasiliana nasi sasa kwa uchakataji wako wa vyuma chakavu!

Know how to do scrap metal recycling quickly? Come and contact us, our metal crusher will provide you with the optimal choice.