Mashine ya moja kwa moja ya kunyoosha taka kwa kuuza

Bar moja kwa moja | Mashine ya kuchakata chuma cha taka

Rätning av stavens diameter: 6-25mm

Rätningsganger: 5 eller 6 hål, 20 gånger/gång

Rätningslängd: 500-2000mm

Tillämpningar: återanvändning i byggkonstruktion, stålbearbetningsanläggningar, skrotrecyklingsstationer och andra områden

Beställningsprocess: kontakta oss→specificera dina krav→välj utrustning→bekräfta beställningen→producera och testa→leverera

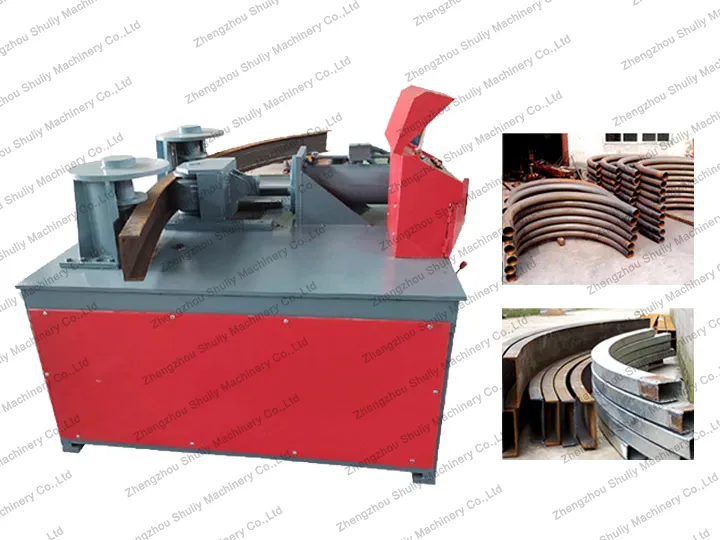

Shuliy armeringsjärn rätande maskin är designad för att räta ut böjda eller deformerade skrotstålstänger (med en diameter på 6-25mm) för återanvändning. Efter rätning minskar volymen av armeringsjärnet, vilket gör det lätt att transportera.

Inayo urefu wa kunyoosha wa 500-2000mm na wakati wa kunyoosha wa mara 20 kwa wakati.

Mashine hii ya kuchakata taka ya chuma inaboresha thamani ya utumiaji wa baa za chuma na hupunguza taka, ambayo hutumiwa sana katika ujenzi wa ujenzi, mimea ya usindikaji wa chuma, vituo vya kuchakata chuma, na uwanja mwingine. Ikiwa unavutiwa, karibu kuwasiliana nasi kwa maelezo zaidi!

Manufaa ya mashine ya kunyoosha chakavu

- Inaweza Baa moja kwa moja au iliyoharibika (6-25mm) na pato la mara 20 kwa wakati, ambayo ni bora.

- Mashine hii ya chuma chakavu ya chuma ina Mashimo 5 au shimo 6 na kulisha-umbo la T., rahisi kulisha na kudumu.

- The Gia imetengenezwa kwa vifaa vyenye unene, Vaa sugu, kuwa na maisha marefu ya huduma.

- The Shindano la joto la juu la kuzima shinikizo linachukua vifaa vya chuma 40, Kufanya Rearr kuwa na athari nzuri ya kunyoosha.

Vigezo vya kiufundi vya mashine ya kunyoosha chuma

| Mfano | 6-10 | 6-14 | 8-16 | 14-25 |

| Kunyoosha kipenyo cha fimbo | 6-10mm | 6-14mm | 8-16mm | 14-25mm |

| Nyakati za kunyoosha | Shimo 5, mara 20/wakati | Shimo 5, mara 20/wakati | Shimo 5, mara 20/wakati | Shimo 6, mara 20/wakati |

| Urefu wa kunyoosha | 500-2000mm | 500-2000mm | 500-2000mm | 500-2000mm |

| Nguvu ya magari | 4kW | 5kW | 5kW | 15kW |

| Uzito wa mashine | 570kg | 730kg | 750kg | 980kg |

| Vipimo vya mashine | 1100*720*1150mm | 1200*7890*1220mm | 1250*820*1300mm | 1550*890*1600mm |

Maombi ya mashine ya kunyoosha taka taka

Mashine yetu ya kunyoosha chakavu hutumika sana katika tasnia nyingi kama ujenzi, daraja, ujenzi wa barabara, kuchakata chuma chakavu, nk Maombi yake kuu ni pamoja na:

- Sekta ya ujenzi: Baa za chuma zilizokataliwa kwenye tovuti ya ujenzi zinaweza kutumika tena kwa ujenzi baada ya kutibiwa na mashine ya kunyoosha ili kupunguza taka.

- Kiwanda cha kusindika bar ya chuma: Inatumika kunyoosha baa za chuma zilizochakatwa kabla ya kukata na kulehemu ili kuboresha thamani ya matumizi ya baa za chuma.

- Kituo cha kuchakata chuma chakavu: Saidia kituo cha kuchakata kusindika rebar ya chakavu vizuri na kuboresha faida ya kiuchumi ya chuma kilichosindika.

- Ujenzi wa darajaBaadhi ya baa za chuma chakavu zinaweza kutumika tena katika ujenzi wa daraja baada ya kunyoosha na usindikaji, kupunguza gharama za ujenzi.

Je! Shuliy Steel Bar inafanyaje kazi?

Mashine ya kunyoosha bar ya pande zote inakamilisha kazi ya kunyoosha kupitia utaratibu wa kunyoosha na mfumo wa traction, na mtiririko wa msingi ni kama ifuatavyo:

- Kulisha: Baa ya chuma iliyoinama au iliyoharibika huingia kwenye mashine kupitia bandari ya kulisha.

- Kunyoosha: Baa hupitia magurudumu kadhaa ya kunyoosha, hutegemea mvutano wa mitambo ili kunyoosha hatua kwa hatua.

- Matokeo ya bidhaa iliyomalizika: Mwishowe pata rebar na moja kwa moja, ambayo inaweza kutumika kwa ujenzi au kuchakata tena.

Je! Ni bei gani ya kunyoosha mashine?

Bei ya mashine ya kunyoosha bar ya pande zote huathiriwa na sababu kadhaa, pamoja na mfano, uainishaji, na nyenzo za vifaa. Aina tofauti za vifaa zina ukubwa tofauti wa uainishaji, zinazoathiri upeo wa programu. Chaguo la nyenzo linahusiana na uimara na maisha ya huduma ya vifaa. Sababu hizi pamoja huamua bei ya mwisho ya vifaa.

Unataka kupata nukuu maalum? Jisikie huru kuwasiliana nasi!

Shuliy: Mtaalam wa Rebar Rebar Kunyoosha Mashine na muuzaji

Shuliy ni mtengenezaji wa kitaalam wa mashine za kunyoosha chuma chakavu na uzoefu mzuri wa uzalishaji na teknolojia ya kukomaa. Bidhaa zetu ni maarufu kwa ubora wa hali ya juu, ufanisi mkubwa na matumizi ya chini ya nishati, ambayo inaaminika na wateja kote ulimwenguni. Tunatoa:

- Aina kamili ya vifaa vya kunyoosha chuma vya chuma kwa mahitaji tofauti

- Msaada wa kiufundi na mafunzo ili kuhakikisha matumizi laini ya vifaa

- Huduma ya haraka baada ya mauzo ili kuhakikisha operesheni thabiti ya vifaa vya muda mrefu

Ikiwa unahitaji mashine bora ya rebar ya rebar, Shuliy ni chaguo lako bora!

Jinsi ya Oder moja taka ya chuma bar ya kuchakata mashine kutoka Shuliy?

Mchakato wa kuagiza ni haraka na rahisi, unaweza kufuata hatua zilizo chini:

- Wasiliana nasi: Wasiliana nasi kupitia habari ya mawasiliano mkondoni upande wa kulia wa ukurasa wa wavuti.

- Sema mahitaji yako: Toa mahitaji yako maalum, kama kipenyo cha rebar, urefu wa kunyoosha, uwezo wa usindikaji, na kadhalika.

- Chagua vifaa: Tutapendekeza mfano sahihi kulingana na mahitaji yako, na kutoa vigezo vya kina na nukuu.

- Thibitisha agizo: Kila kitu kimethibitishwa, wote saini mkataba na kulipa amana.

- Uzalishaji na upimaji: Tutakamilisha uzalishaji ndani ya wakati uliowekwa na mtihani ili kuhakikisha ubora wa mashine.

- Usafirishaji: Vifaa vya kunyoosha chuma vitapelekwa na bahari (kawaida) na kufika kwenye marudio kwa wakati.

Wasiliana nasi sasa kwa maelezo zaidi!

Förutom armeringsjärn rätande maskin tillhandahåller vi också olika utrustningar för bearbetning av stålstänger, såsom maskin för tillverkning av armeringsringar, stirrup bender, rörböjningsmaskin, etc.

Om du är intresserad, eller vill veta den specifika modellen, priset och annan information, är du välkommen att kontakta oss när som helst. Vi tillhandahåller detaljerna och den mest lämpliga lösningen för din stålstänger bearbetningsverksamhet.