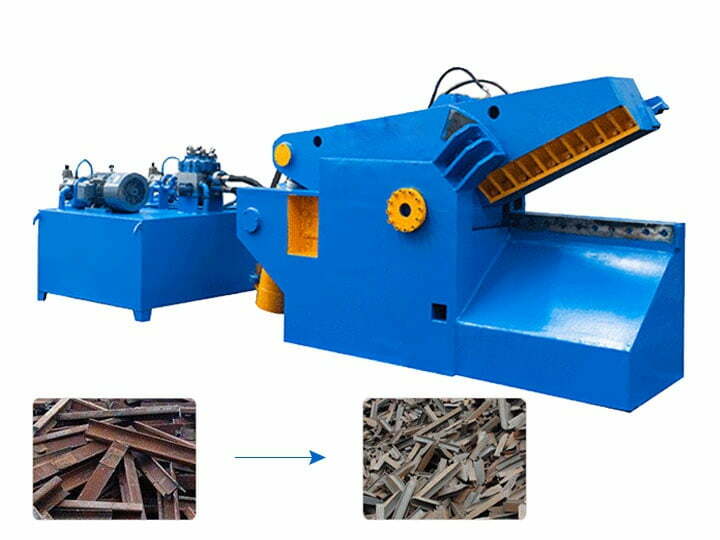

Jinsi ya Kudumisha Blade za Kukata za Alligator Metal Shear?

Metal alligator shears ni aina mpya ya vifaa vya usindikaji wa chuma chakavu, ambayo ina jukumu muhimu katika sekta ya kuchakata chakavu. Mikasi ya chuma hutumika zaidi katika mitambo ya kuchakata chuma, maeneo ya kubomoa magari chakavu, na viwanda vya kuyeyusha vyuma ili kukata na kukata maumbo mbalimbali ya chuma na vifaa mbalimbali vya chuma. Wakati wa matumizi ya cutter hii ya chuma, utunzaji lazima uchukuliwe ili kudumisha vile vile.

Sifa kuu za mashine ya kukata mamba

1. Hii mkataji wa mamba hutumika zaidi katika tasnia ya usindikaji wa kuchakata taka. Kukata baridi kwa mitambo mbalimbali ya chuma ndogo na ya kati kama vile chuma cha mviringo, chuma cha mraba, chuma cha njia, chuma cha pembe, chuma cha umbo la I, sahani za chuma, mabomba ya chuma na metali nyingine za taka.

2. Kifaa hiki kinatumia maambukizi ya majimaji. Ikilinganishwa na shears za upitishaji wa mitambo, ina faida za saizi ndogo, nyepesi, hali ya chini, kelele ya chini, harakati thabiti, operesheni salama, na utumiaji, na rahisi kufikia ulinzi wa upakiaji.

3. Cutter hii ina kazi za uendeshaji wa mwongozo na uendeshaji wa moja kwa moja. Njia yake ya uendeshaji ni rahisi na rahisi. Kinywa cha mkasi wa chuma kinaweza kukatwa na kusimamishwa kwa nafasi yoyote wakati wa kazi. Na kwa mujibu wa ukubwa wa nyenzo zinazokatwa, ukubwa wa mdomo wa kukata unaweza kudhibitiwa kiholela ili kufikia ufanisi wa juu wa kazi.

Njia za matengenezo ya vile vya kukata chuma

1. blade ya mashine ya kunyoa chuma inapaswa kuhifadhiwa mahali pa baridi na kavu. Ili kuzuia blade kutoka kutu, safu ya mafuta ya kupambana na kutu inapaswa kutumika kwa blade iliyotumiwa. Visu ambazo hazijafunguliwa zinapaswa kuhifadhiwa mahali pakavu kwenye sehemu iliyofungwa ili kuzuia vile vile kushika kutu.

2. Katika matumizi halisi ya mashine ya kukata chuma ya majimaji, ni muhimu kufanya kazi madhubuti kwa mujibu wa "sheria za uendeshaji wa mashine ya kukata chuma ya hydraulic", na matumizi sahihi ya mashine hii inaweza kuhakikisha ufanisi wa juu wa kazi.

3. Kabla ya kila matumizi ya shear ya alligator, mafuta ya kulainisha yataongezwa mara kwa mara, kwa usahihi na kwa kiasi kulingana na mahitaji ya chati ya lubrication. Vilainishi vinapaswa kuwekwa safi na bila mashapo. Kusisitiza juu ya kiasi sahihi cha mafuta ya kulainisha ili kuweka uso wa blade safi na kuboresha upinzani wa kuvaa wa uso wa blade.

4. Vipande vya shears za chuma lazima ziwe safi kila wakati, na sehemu ambazo hazijapakwa zinapaswa kuvikwa na grisi ya kuzuia kutu.

5. Angalia mara kwa mara matumizi na kuvaa kwa blade. Ikiwa blade imevaliwa sana, inapaswa kubadilishwa kwa wakati, na blade mpya inapaswa kubadilishwa kwa wakati.

6. Blade ya mashine ya kukata nywele inapaswa kuhifadhiwa kwenye sanduku la mbao kali wakati wa usafiri. Uso wa sanduku la mbao unapaswa kufunikwa na nyenzo za povu ili kuzuia kuhama na mgongano wakati wa usafirishaji. Maneno "sehemu tete" yanapaswa kuwekwa alama kwenye nje ya sanduku ili kuvutia tahadhari. Wakati wa kufuta kwenye warsha, zuia blade isiharibike.