Wima Metal Baler | Vyombo vya habari vya Baling ya Hydraulic

| Chapa | Shuliy |

| Uwezo | 6-10 marobota kwa dakika |

| Ukubwa wa bale | 800*400*800mm, 800*400*600mm, 1150*750*1000mm, nk. |

| Chakavu kuwa baled | Chuma, chuma, alumini, shaba, risasi, zinki, nk. |

| Faida | Ufanisi wa juu, ufanisi wa gharama, ubinafsishaji, nk. |

| Kipindi cha udhamini | Miaka 1-2 |

Sasa unaweza kuwauliza wasimamizi wetu wa mradi kwa maelezo ya kiufundi

Shuliy vertikal metallbaler är avsedd att komprimera alla slags metallavfall (såsom skrotstål, skrotiumne, skrotsilver, etc.) till block genom hög tryck. Efter pressning är de balerade metallettarna för enkel lagring, transport och återvinning.

Mashine ina kasi ya kupeana kati ya marobota 6-10 kwa dakika. Inaweza kubonyeza marobota yenye ukubwa wa 800*400*800mm, 800*400*600mm, 1150*750*1000mm, n.k. Tunaweza kubinafsisha saizi ya bale ili kutimiza matakwa yako.

Vyombo vya habari vya hydraulic baling ina faida za uendeshaji rahisi, matumizi pana, na gharama nafuu.

Baler yetu ya wima pia inaweza kutumika kwa kuweka katoni, nguo, chupa za plastiki, na kadhalika. Ikiwa una nia, tafadhali jisikie huru kuwasiliana nasi.

Manufaa ya Shuliy hydraulic baling press

- Uwezo wa marobota 6-10 kwa dakika. Baler yetu hutumia mfumo wa majimaji wenye nguvu kushinikiza upotevu wa marobota 6-10 kwa dakika moja, ambayo ni nzuri.

- Paneli ya kudhibiti yenye akili na kiolesura angavu cha mtumiaji. Muundo huu unafaa kwa watumiaji. Hata kama wewe ni mtu mpya unaweza kuanza haraka.

- Baling aina nyingi za vifaa vya chuma. Baler hii ya wima ya chuma inafaa kwa aina nyingi za taka za chuma kama vile chuma chakavu, alumini chakavu, shaba chakavu, n.k.

- Ufanisi wa gharama. Sisi ni mauzo ya moja kwa moja ya kiwanda. Kwa teknolojia iliyoboreshwa, tunaweza kuzalisha bati kwa makundi, kuhakikisha ubora huku tukipunguza bei, ambayo ni ya gharama nafuu.

- Gharama ya chini ya matengenezo. Muundo wa vifaa ni rahisi na rahisi kuelewa. Matengenezo ya kila siku ni rahisi sana na ya gharama nafuu.

- Nguvu ya ukandamizaji inayoweza kubinafsishwa, saizi ya kizuizi iliyoshinikwa na zingine. Kulingana na mahitaji yako, tunaweza kubinafsisha hizi. Pia, tunaweza kubinafsisha voltage, nguvu, nk.

Vigezo vya kiufundi vya baler ya chuma ya wima ya majimaji

| Mfano | SL-10T | SL-20T | SL-30T | SL-60T | SL-80T |

| Nguvu | 5.5 kW | 7.5 kW | 11 kW | 15 kW | 17 kW |

| Ukubwa wa bale | 800*400*800mm | 800*400*800mm | 800*400*600mm | 1150*750*1000mm | 1150*750*1000mm |

| Shinikizo | 10t | 20t | 30t | 60t | 80t |

| Dimension | 1400*700*2900mm | 1400*700*2950mm | 1450*800*2950mm | 1700*1000*3200mm | 1800*1000*3200mm |

| Silinda ya mafuta | φ125 | φ160 | φ160 | φ160 | φ180 |

| Kasi ya kulipuka | 8-10 bales kwa dakika | 8-10 bales kwa dakika | 8-10 bales kwa dakika | 6-10 bales kwa dakika | 6-10 bales kwa dakika |

| Uzito | 400kg | 850kg | 950kg | 1600kg | 2000kg |

Vyombo vya habari vyetu vya kuhifadhia majimaji vina miundo mbalimbali ya kuuza, mtawalia SL-10T, SL-20T, SL-30T, SL-60T, SL-80T, nk. Ikiwa una nia, karibu kuwasiliana nasi kwa maelezo zaidi!

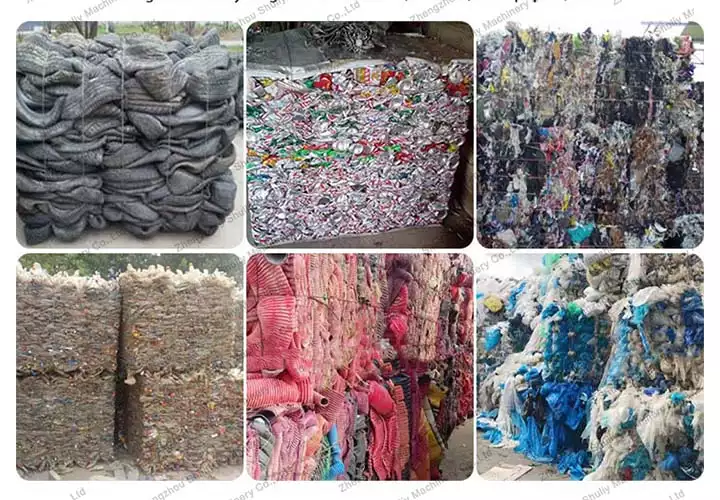

Taka za chuma na mabaki mengine ya kupigwa baled

Baler yetu ya wima ina kazi nyingi na inafaa kwa kila aina ya ukandamizaji wa nyenzo za taka. Sasa, nitaanzisha nyenzo chakavu ambazo zinaweza kupigwa baled.

- Chuma chakavu

- Chuma cha taka, sahani za chuma, mabomba ya chuma, baa za chuma na vifaa vingine vya chakavu katika aina mbalimbali.

- Alumini chakavu

- Makopo chakavu ya alumini, sahani za alumini, zilizopo za alumini, foil ya alumini na aina nyingine za vifaa vya alumini.

- Chakavu cha shaba

- Taka za waya za shaba, mabomba ya shaba, sahani za shaba, chips za shaba, nk.

- Chuma chakavu

- Aina mbalimbali za vifaa vya chuma kama vile chuma chakavu, chakavu cha chuma, waya wa chuma, sahani ya chuma, nk.

- Chakavu cha chuma cha pua

- Taka vifaa vya chuma cha pua, sahani ya chuma cha pua, bomba la chuma cha pua na aina zingine za nyenzo za chuma cha pua.

- Uongozi chakavu

- Karatasi ya risasi ya taka, bomba la risasi, block block na aina zingine za vifaa vya risasi.

- Mabaki ya zinki

- Sahani ya zinki, bomba la zinki, block ya zinki na vifaa vingine vya taka vya zinki.

- Aloi taka

- Kila aina ya vifaa vya aloi ya chuma taka, kama vile aloi ya shaba, aloi ya alumini, aloi ya nikeli na kadhalika.

- Mabaki ya elektroniki

- Sehemu za chuma katika bidhaa za elektroniki za taka, kama vile waya, na bodi za mzunguko katika vipengele vya chuma.

- Wengine: mpira wa taka, nguo, kadibodi ya taka, mabomba, chupa za plastiki, makopo, povu, sifongo, nk.

Utumizi wa mashine ya kuwekea wima ya Shuliy

Baada ya kujua vifaa vya chakavu kuwa marobota, sasa hebu tuone matumizi yake.

- Kituo cha kuchakata chuma chakavu

- Hutumika kubana mabaki mbalimbali ya chuma kuwa vizuizi kwa urahisi wa usafirishaji na utumiaji tena.

- Kiwanda cha usindikaji wa chuma

- Chakavu cha chuma kilichoshikana kilichozalishwa katika mchakato wa uzalishaji katika vitalu. Hii inaweza kupunguza nafasi ya kuhifadhi na kuboresha matumizi ya rasilimali.

- Vituo vya kukusanya chakavu

- Compress mabaki mbalimbali ya chuma kununuliwa katika vitalu. Hii inaboresha ufanisi wa usafiri na kupunguza gharama.

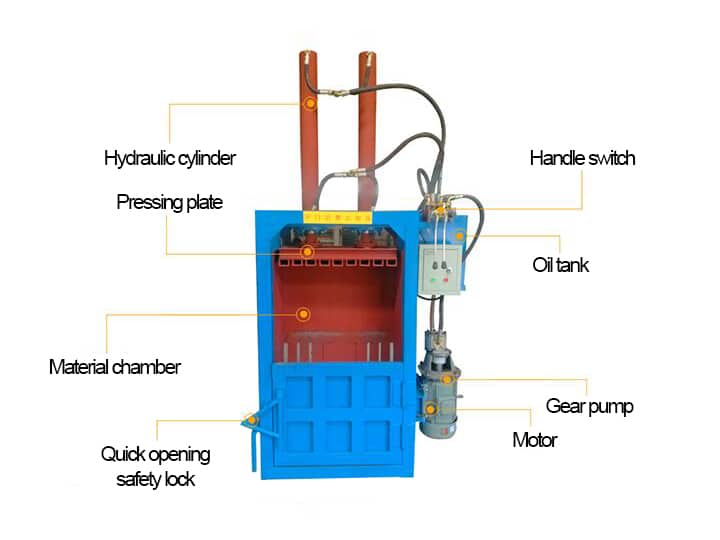

Muundo wa baler ya wima ya hydraulic

Muundo wake ni pamoja na silinda ya majimaji (mbili), chumba cha nyenzo, ufunguzi wa haraka, swichi ya mkono, tanki la mafuta, pampu ya gia, na motor.

Ikilinganishwa na baler ya aina ya mlalo, baler hii ya wima ndiyo ndogo zaidi na inayotumiwa sana. Kawaida hutumiwa kwa mimea ndogo na ya kati ya kuchakata taka. Ikiwa una nia, karibu kuwasiliana nasi kwa maelezo zaidi!

Mchakato wa kufanya kazi wa mashine ya kusawazisha wima

Inapakia

Weka chakavu cha chuma kwenye chumba cha mgandamizo cha baler ya wima ya chuma.

Mfinyazo

Washa mfumo wa majimaji na bamba la mbano litasogea chini ili kubana chakavu cha chuma kuwa vizuizi.

Shinikizo la nguvu la majimaji huhakikisha kuwa chakavu kinasisitizwa kwa kiwango cha chini.

Kufunga kamba

Mara mbano kukamilika, mashine hufunga kiotomatiki/kwa mikono vifurushi vilivyobanwa. Hii inazifanya kuwa ngumu kwa utunzaji na uhifadhi rahisi.

Kutoa

Baada ya kukandamizwa na kufungwa, mashine husukuma moja kwa moja vizuizi vya chuma vilivyobanwa. Kisha mashine iko tayari kwa kundi linalofuata la chakavu kukandamizwa.

Tahadhari za kutumia mashine ya hydraulic metal baler

Ili kutumia kwa usahihi mashine hii ya wima ya baler ya chuma, unapaswa kujua muundo wa mashine na taratibu za uendeshaji. Pia, kuna baadhi ya pointi unapaswa kuzingatia.

- Mafuta ya majimaji yenye ubora wa juu yanapaswa kutumika kwa ukali kuongeza mafuta ya majimaji kwenye tanki ya mafuta.

- Chuja kabisa mafuta ya majimaji na udumishe kiwango cha kutosha cha mafuta mara kwa mara.

- Jaza mafuta mara moja wakati haitoshi.

- Safisha tanki la mafuta la wima la chuma na uweke mafuta mapya kila baada ya nusu mwaka.

- Kusafisha kwanza na kuchuja mafuta haipaswi kuzidi mwezi mmoja.

- Mafuta mapya ambayo yametumika mara moja yanaweza kutumika tena baada ya kuchujwa kwa ukali.

- Sehemu za kulainisha za mashine hii ya wima ya baler zinapaswa kujazwa na mafuta ya kulainisha angalau mara moja kwa zamu inavyohitajika.

- Safisha sehemu zote kwenye sanduku la nyenzo kwa wakati.

- Usianze mashine bila kujifunza na kuelewa muundo wake, utendaji na taratibu za uendeshaji.

- Katika kesi ya uvujaji mkubwa wa mafuta au hali isiyo ya kawaida wakati wa operesheni, simamisha mashine mara moja.

- Kuchambua sababu na kuondoa makosa.

- Uendeshaji wa kulazimishwa na hitilafu hauruhusiwi.

- Wakati wa operesheni ya baler ya chuma ya wima ya majimaji, hairuhusiwi:

- Rekebisha au wasiliana na sehemu zinazohamia.

- Bonyeza nyenzo kwenye sanduku la nyenzo kwa mikono au miguu yako.

- Wakati wa kurekebisha pampu, valve na kupima shinikizo, lazima ifanyike na wafundi wenye ujuzi.

- Ikiwa kipimo cha shinikizo kinapatikana kuwa kibaya, kinapaswa kuchunguzwa au kubadilishwa mara moja.

- Unapaswa kuunda taratibu za kina za matengenezo na usalama kulingana na hali maalum.

Wasiliana nasi kwa suluhu za kuchakata taka!

Letar du efter kostnadseffektiva lösningar för metallavfall återvinning? Vi har vertikal metallbaler och horisontell metallbaler för att gagna din verksamhet.

Ikiwa una nia, wasiliana nasi sasa na tutakupa suluhisho bora zaidi!