スクラップ切断用金属シャーマシーン

| ブランド | シュリー |

| 容量 | 5〜8回/分(調整可能) |

| 原材料 | 丸鋼、角鋼、溝形鋼、アングル鋼、ビーム、プレート、鋼管、鋼板、Iビームなど |

| 一致したデバイス | チェーンプレートコンベヤ |

| 利点 | 高効率、強力なせん断用途、簡単な操作性など。 |

技術的な詳細についてプロジェクト マネージャーに問い合わせることができるようになりました

Shuliyの金属シャーマシン(「タイガーヘッドシャーリングマシン」とも呼ばれます)は、軽鋼材、銅管、鉄板などのスクラップ金属を必要なサイズに切断するためのものです。金属くずを1分間に5〜8回切断でき、調整可能です。

当社の油圧金属切断機は、作業幅1mと1.2m(刃の開口サイズ)を持っています。お客様のご要望に合わせてカスタマイズすることも可能です。

この機械には、廃金属をプレスする刃とスクラップを切断する刃の 2 枚が付いています。金属切断に便利なチェーンフィーダーをオプションでご用意しています。

当社の油圧式金属せん断機は、強力なせん断用途、安全で簡単な操作、連続切断、高い生産効率により非常に人気があります。

鋼管などのスクラップの解決策をお探しの場合、この金属切断ハサミは理想的な選択肢です。

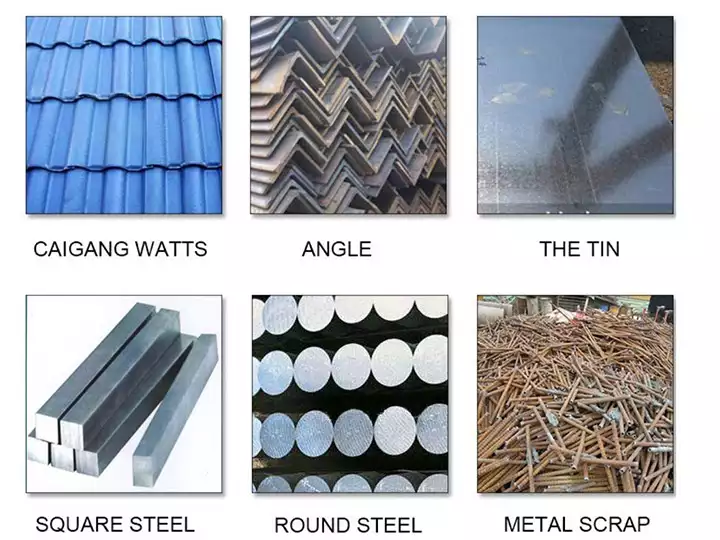

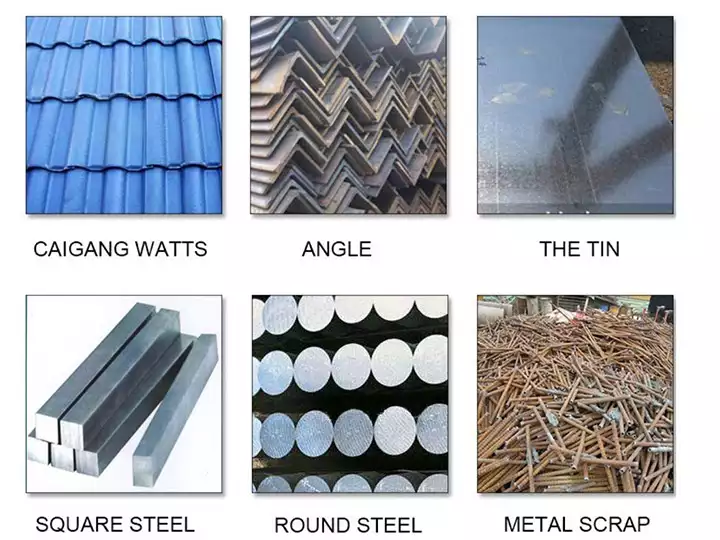

切断対象金属スクラップと金属シャーリングマシンの用途

当社の金属剪断機は、次のようなさまざまな金属スクラップを切断できます。

丸鋼、角鋼、チャンネル鋼、アングル鋼、梁、プレート、鋼管、鋼板、Iビーム、アルミニウム塊、鉄板、銅管など

タイガーヘッド油圧式メタルハサミで切断できる金属が分かったところで、どのような場所や業界で使われているのでしょうか?

この種の金属切断機は次の分野で広く使用されています。

- 金属スクラップのリサイクルおよび処理ステーション

- 製鉄所および製鋼所

- 冶金産業

- 大規模スクラップリサイクルセンター

油圧式金属せん断機の利点

- 毎分5〜8回の速度で金属廃材を切断します(調整可能)。当社の金属切断機は、1分間に5〜8回の廃金属を切断することができ、効率的です。カット時間を調整することもできます。

- 鋼板、鋼管、鉄くず、鉄くず、アルミ等のせん断。 Shuliy 板金カッター マシンは、さまざまな金属材料を切断することができます。幅広い応用範囲があります。

- チェーンフィーダーによる連続切断。便利で中断のない切断のために、当社のハサミはチェーンプレートコンベアを追加することができ、より便利で高速になります。

- 簡単操作。スクラップ金属剪断機は合理的に設計されています。作業者は短期間のトレーニングを経て、機器の使い方を習得できます。

板金せん断の技術パラメータ 機械

| モデル | SL-250 | SL-300 |

| 最大。せん断力 | 2500KN | 2500KN |

| シャーシリンダーストローク | 450mm | / |

| 最大。プレス力 | 2500KN | 2500KN |

| プレスシリンダーストローク | 450mm | / |

| 作業台の高さ | 800mm | 800mm |

| 容量 | 5〜8回/分(調整可能) | 5〜8回/分(調整可能) |

| シャーナイフの作動長さ | 1000mm | 1000mm |

| 最大。対応するブレードの開口部 | 550mm | / |

| 油圧ポンプ | 80YCY | / |

| モーター出力 | 22kw | 22kw |

| 主機寸法 | 2000*1200*1800mm | 2000*1200*2100mm |

| 油圧ステーションのサイズ | 1600*1200*1400mm | / |

上記のパラメータは、金属剪断機を選択する際の参考用です。

材質、厚み等をお知らせいただければ、弊社営業担当が最適な機種をご提案させていただきます。

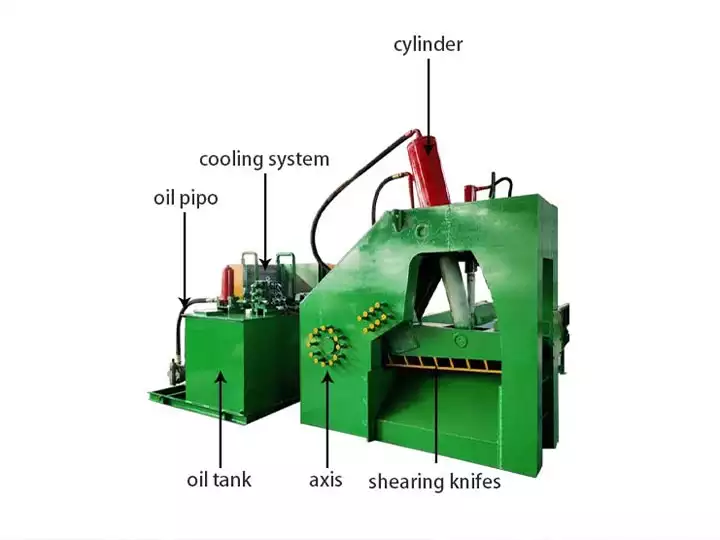

スクラップシャーマシンの構造

スクラップ金属せん断機には、主にせん断オイルシリンダー、せん断ナイフ、スライディングブロックプレスナイフ、下部ナイフシート、プレスオイルシリンダーなどが含まれています。

本体と油圧シリンダーが別体になっており、安全にご使用いただけます。

金属せん断機の動作原理

タイガーヘッド金属剪断機の動作原理は、油圧システムを使用してカッターヘッドを駆動することです。

金属廃材をカッターヘッドの下に置き、油圧の力でカッターヘッドを押し下げると切断が完了します。

せん断された金属ブロックは必要なサイズに調整できるため、保管や持ち運びが簡単です。

金属シャーカッター用補助装置

油圧式金属シャーリングマシンはチェーンプレートフィーダーに接続して自動供給することができます。

チェーンプレートフィーダーにより、従来の搬送機構のような材料の膨らみを回避し、スムーズな供給を実現します。

金属切断機の選び方のポイント

金属ハサミを購入するときは、その装置が加工要件を満たすことができるかどうかを確認することが重要です。

経済的で実用的な油圧金属切断機を購入するには、次の点に注意することをお勧めします。

- 廃棄物のサイズと材質を明確にする。これは、剪断の効率と有効性を確保するために適切な機械のトン数を選択するのに役立ちます。

- 特殊な材料には特殊な刃を選択してください。特殊な材料や廃棄物は硬度が高くなります。そのため、交換の手間を軽減するために専用の刃が必要になります。

- 設置と操作が簡単な機器を選択する。設備一体型のため、複雑な設置工事が不要で操作が簡単で、作業効率の向上に貢献します。

詳細については今すぐお問い合わせください。

スクラップ金属シャーリングのソリューションをお探しなら、お問い合わせください!

このシャーの他に、アリゲーターシャーとガントリーシャーマシンもあります。どのような種類のスクラップでも対応できます。