¿Cómo elegir una máquina de fabricación de anillos de refuerzo adecuada?

Al prepararse para comprar una máquina de fabricación de anillos de barras, puede comenzar con las necesidades de producción reales, el rendimiento de la máquina, la funcionalidad y el soporte de servicios del equipo. A continuación se muestra la descripción detallada de su referencia.

¿Puede la capacidad de producción satisfacer la demanda del proyecto?

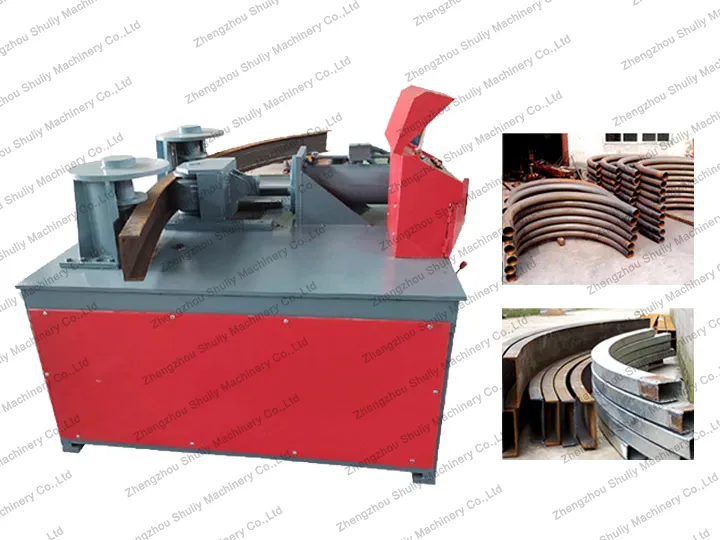

Para proyectos de construcción, infraestructura, plantas de energía fotovoltaica y otros proyectos, la carga de trabajo es grande, el cronograma es apretado y la capacidad de producción del equipo tiene altos requisitos. La máquina de anillado de varilla de Shuliy adopta un sistema hidráulico de alta eficiencia y un mecanismo de transmisión estable. La máquina completa admite un procesamiento automatizado continuo y puede producir múltiples anillos de varilla por minuto, lo que mejora enormemente la eficiencia de producción y asegura que el proyecto se entregue a tiempo.

¿Puede admitir el procesamiento de múltiples tamaños de refuerzo?

Diferentes proyectos tienen diferentes requisitos para los tamaños de refuerzo, como φ8mm-φ12mm, etc. La máquina de hacer anillo de refuerzo de barra de refuerzo está diseñada para ser flexible y admite el procesamiento de las barras de refuerzo de múltiples diámetros. Solo necesita elegir el equipo correspondiente a los diferentes tamaños de barras de refuerzo, que ofrecen amplias opciones.

¿Está operado CNC? ¿Es fácil de usar?

Muchos clientes están preocupados por la complejidad operativa del equipo, especialmente los nuevos empleados que tardan en comenzar. Nuestra máquina enrollable de resorte está equipada con un sistema de control numérico CNC inteligente, que puede establecer el tamaño del círculo, la longitud y el número de procesamiento automático. La interfaz de operación es intuitiva y simple. Los operadores ordinarios pueden dominarlo después de una simple capacitación, reduciendo en gran medida los costos laborales y el tiempo de capacitación.

¿Es alto el mecanizado de precisión? ¿El efecto de moldeo es regular?

Si la forma del círculo es irregular y el error de tamaño es grande, afectará fácilmente la calidad de la construcción. Shuliy Rebar Ring Machine adopta un sistema de control hidráulico de alta precisión y un dispositivo de guía, con alta precisión de flexión, buena redondez y pequeño error (± 0.2 mm). Cada círculo de barras procesado es uniforme y hermoso, lo cual cumple plenamente con los estándares de ingeniería.

¿Está garantizado el servicio postventa? Incluir instalación y capacitación?

No importa cuán buena sea la calidad de la máquina para hacer círculos de varilla, no se puede separar del soporte de servicio perfecto. Shuliy cuenta con un equipo profesional de servicio postventa para proporcionar:

- Guía de instalación de equipos uno a uno

- Capacitación de operación remota o en el sitio

- Manual de equipos y video de operación

- Soporte técnico gratuito y reemplazo de piezas durante el período de garantía

Prometemos: después de la llegada del equipo del cliente, simplemente conecte la fuente de alimentación y se puede poner en uso rápidamente de acuerdo con las instrucciones sin preocuparse por los problemas posteriores a la venta.

¿Por qué elegir Shuliy Rebar Ring Machine?

- Estructura estable, larga vida útil: los componentes centrales están hechos de acero engrosado y un sistema hidráulico de alta calidad, que es resistente al desgaste y duradero.

- Operación conveniente, alta eficiencia: el sistema CNC totalmente automático es fácil de operar y admite la configuración por lotes y la producción repetitiva.

- Admite personalización de múltiples especificaciones: se pueden personalizar diferentes moldes de acuerdo con la demanda del cliente para barra de refuerzo tamaños.

- Garantía de servicio perfecta: proporcionamos instalación y depuración, capacitación técnica y soporte postventa uno a uno para garantizar que pueda usarlo sin preocuparse.

Como proveedor profesional de máquinas de barras de refuerzo, Shuliy proporciona una variedad de modelos, personalización personalizada y servicio posterior integral. Bienvenido a preguntar sobre las cotizaciones de la máquina.