Máquina de flexión de barras espiral de CNC para la fabricación de aros de la barra

Máquina de fabricación de anillos de parar | Máquina de enrollamiento de primavera

Diámetro de la barra de acero aplicable: 3-25 mm

Anillos de barras de refuerzo terminados Diámetro: 50-3000 mm

Velocidad de viaje: 16-30m/min

Error de trabajo: ± 0.2 mm

Aplicaciones de anillos de barra de acero: riel de alta velocidad, metro, puente, estación de energía fotovoltaica, ingeniería de construcción y otros campos

La máquina dobladora de espiral Shuliy puede procesar rápida y con precisión barras de acero de 3-25 mm en anillos redondos con un diámetro de 50-1000 mm. Produce principalmente anclajes de pilotes de tierra, utilizados en ferrocarriles de alta velocidad, metros, energía fotovoltaica y otros proyectos.

Los círculos producidos por esta máquina de fabricación de anillos de refuerzo pueden ser uno o conectado, principalmente dependiendo de la demanda del cliente. Si está interesado, ¡bienvenido a contactarnos para más detalles!

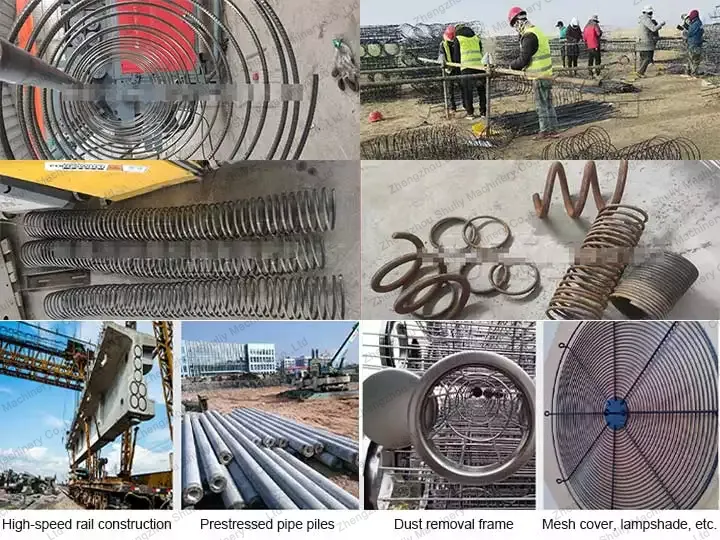

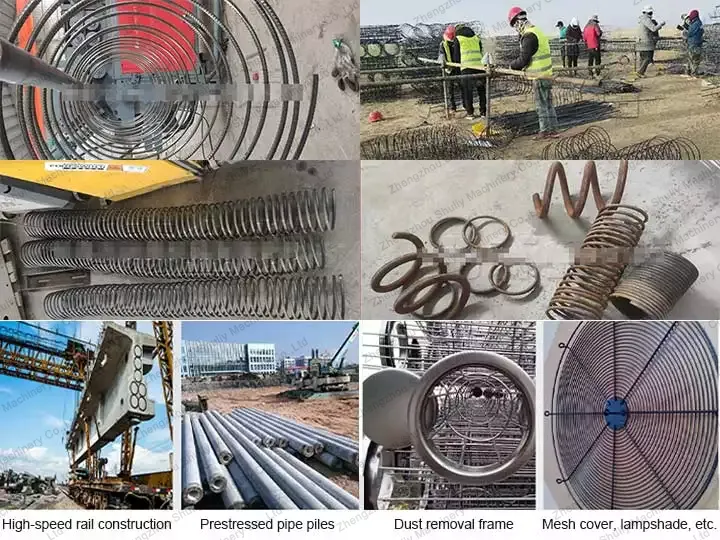

Productos terminados y aplicaciones de la máquina de flexión de barras espirales

La máquina de formación de barras espirales se usa principalmente para procesar varias especificaciones de la barra espiral y redonda en círculos con diferentes diámetros (que se muestran a continuación), ampliamente utilizados en riel de alta velocidad, metro, puente, estación de energía fotovoltaica, ingeniería de construcción y otros campos.

- Anclaje de pila: Utilizado para refuerzo y apoyo de fundamentos en ferrocarriles de alta velocidad, metro y otros proyectos.

- Construcción de edificiosN: Utilizado para fabricar componentes de barra de acero redondo para varias estructuras de edificios.

- Estación de energía fotovoltaica: Se utiliza para el refuerzo de la base de los montajes fotovoltaicos para mejorar la estabilidad de la instalación.

- Construcción de puentes: para procesar barras de acero espiral para estructuras de puentes para mejorar la estabilidad del puente.

Ventajas de la máquina de formación de barras espirales de Shuliy CNC

- Nuestra máquina puede procesar refuerzo con un diámetro de 3-25 mm y hacer círculos con un diámetro de 50-3000 mm.

- Shuliy CNC Máquina de redondeo de refuerzo completamente automática tiene una Velocidad de trabajo de 16-30m/min y un Error de trabajo de ± 0.2 mm.

- Adopta un Sistema de control del PLC, realizando una operación completamente automática, que es altamente eficiente.

- Esta máquina de flexión redonda de aro espiral tiene una estructura resistente, operación estable, adecuada para el procesamiento de gran volumen.

- El interfaz intuitiva es simple y fácil para los operadores comenzar.

Parámetros técnicos de la máquina de flexión de barras espirales automáticas

| Modelo | 3-6 | 6-10 | 8-12 | 10-14 | 16-20 | 22-25 |

| Diámetro de la barra de acero aplicable | 3-6 mm | 6-10 mm | 8-12 mm | 10-14 mm | 16-20 mm | 22-25 mm |

| Potencia total del motor | 4kw | 5.5kw | 7kw | 7kw | 11kw | 15kw |

| Diámetro de anillo de barra de acero terminado | 50-1000 mm | 50-800 mm | 50-1500 mm | 50-1800 mm | 50-2200 mm | 50-3000 mm |

| Velocidad de viaje | 16-25m/min | 16-25m/min | 16-25m/min | 16-25m/min | 16-30m/min | 16-30m/min |

| Error de trabajo | ± 0.2 mm | ± 0.2 mm | ± 0.2 mm | ± 0.2 mm | ± 0.2 mm | ± 0.2 mm |

| Dimensiones generales | 1.45*0.8*1.2m | 1.55*0.8*1.3m | 1.55*0.8*1.3m | 1.6*0.8*1.35m | 2.1*0.9*1.5m | 2.3*0.9*1.7m |

| Peso de la máquina | 480 kg | 560 kg | 640 kg | 690 kg | 1150 kg | 1350 kg |

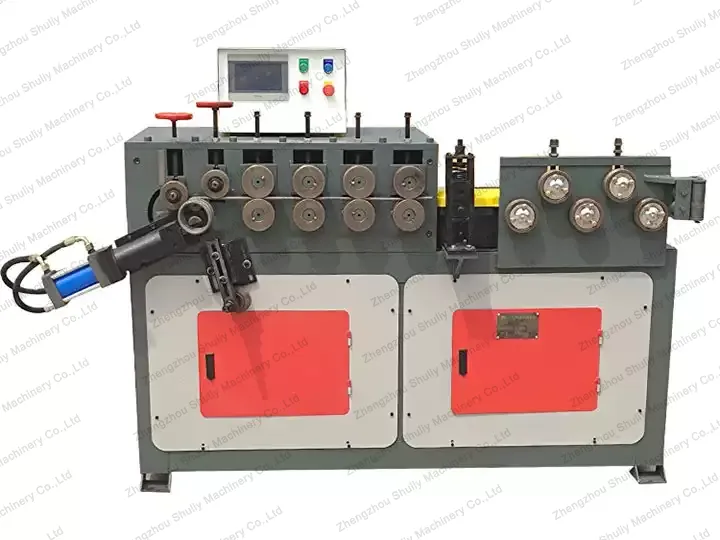

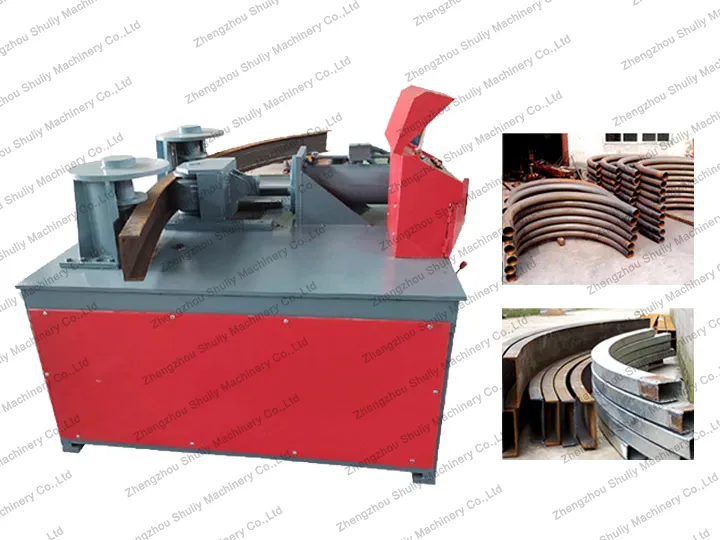

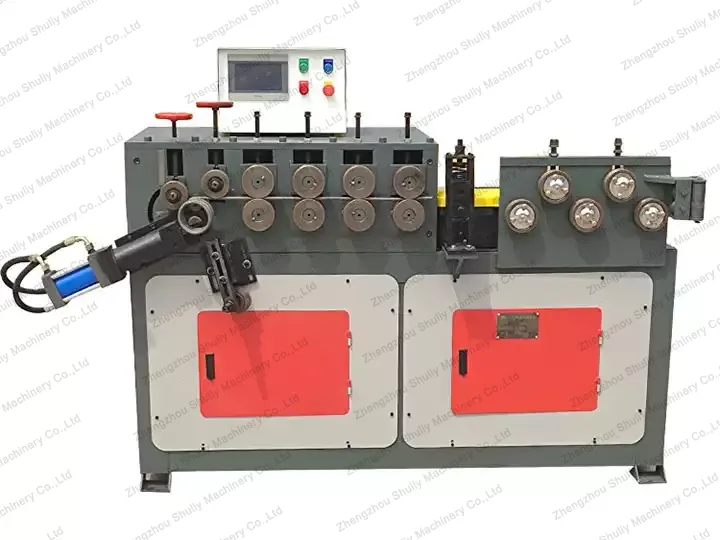

Estructura de la máquina de flexión de barras espirales

Esta máquina de bobina de primavera está hecha de motor, componentes hidráulicos (bomba de aceite, motor hidráulico, válvula solenoide, tanque de aceite, tubería de aceite, etc.), rueda previa al ajuste, enderecedía en la caja de cambios, componente de redondeo, componente de corte, sistema de control eléctrico CNC, etc.

¿Cómo funciona la máquina de hacer anillo de refuerzo?

Nuestra máquina de flexión de barras espirales es conducida por una placa principal del PLC para iniciar el motor de control para conducir la bomba de aceite. Comience los componentes hidráulicos para conducir la caja de cambios de alisión para que funcione, luego conduzca el material para avanzar y muévase al conjunto de redondeo para completar el moldura de redondeo. Finalmente, corte el cilindro de aceite para cortar el material hacia arriba para completar la operación.

- Alimentación de barras de acero: La barra de acero ingresa a la máquina de fabricación de anillos de refuerzo, y el sistema de alisado asegura la rectitud.

- Doblar y formar: La barra de refuerzo pasa a través del molde de flexión para el procesamiento de la ronda espiral.

- Corte: El mecanismo de corte corta la barra moldeada y completa todo el flujo de trabajo.

¿Cuál es el precio de la máquina de bobina de resorte?

El precio de la máquina de flexión de las barras espirales se ve afectado por muchos factores, que incluyen:

- Especificaciones de equipos: Diferentes modelos de máquinas de fabricación de anillos de refuerzo tienen diferentes barras de refuerzo de procesamiento con diferentes precios.

- Capacidad de procesamiento: El equipo de alta potencia y alta eficiencia es relativamente costoso.

- Requisitos de configuración: La configuración personalizada puede afectar el precio de la máquina de fabricación de anillos de refuerzo.

- Condiciones de mercado: El costo de las materias primas, la oferta y la demanda afectará la cita final.

Si desea conocer la última oferta sobre la máquina de flexión de la espiral de barras, puede contactarnos directamente para obtener información detallada.

¿Por qué comprar Shuliy Spiral Rebarking Machine?

Shuliy se compromete a proporcionar equipos de procesamiento de acero de alta calidad y alto rendimiento, las razones para elegir la máquina de flexión de acero espiral shuliy incluyen:

- Seguro de calidad: Utilizamos materiales de alta calidad para fabricar equipos de fabricación de anillos de barra de acero, duradero y estable.

- Tecnología avanzada: Nuestra máquina adopta el control inteligente PLC, que tiene un alto grado de automatización.

- Precio asequible: Fabricamos la máquina y la vendemos directamente desde nuestra fábrica, que tiene un precio competitivo en el mercado.

- Servicio de presentación sin preocupaciones: Shuliy proporciona soporte técnico y mantenimiento de equipos, para garantizar la estabilidad a largo plazo de la operación.

¡Contáctenos para una cotización ahora!

Como fabricante y proveedor profesional de equipos de procesamiento de acero, tenemos diferentes máquinas de procesamiento de barras de corrugado, como máquina enderezadora de barras de corrugado, dobladora de estribos, máquina dobladora de tubos CNC, etc.

Si está interesado en nuestra máquina dobladora de espiral para barras de corrugado u otro equipo para el procesamiento de barras de acero, ¡no dude en contactarnos a través de WhatsApp, WeChat, teléfono o correo electrónico! ¡Le ofreceremos información detallada sobre precios!