Υδραυλικό ψαλίδι για κοπή μετάλλων

| Hot-seller μοντέλο | SLY-200T |

| Μέγ. δύναμη κοπής | 200 τ |

| Πίεση συστήματος | ≤25Mpa |

| Μέγεθος κάδου | 700*1600*2300 χλστ |

| Μήκος λεπίδας | 1200 χλστ |

| Ικανότητα | 2,5-3t/h |

| Διατμητική δύναμη | 4-6 φορές/λεπτό |

| Εξουσία | 2*18,5 kW |

| Βάρος | 11t |

Τώρα μπορείτε να ρωτήσετε τους διαχειριστές του έργου μας για τεχνικές λεπτομέρειες

Το ψαλίδι γάντζου Shuliy (υδραυλική μηχανή ψαλιδίσματος μετάλλων ή ψαλίδι λαμαρίνας) χρησιμοποιείται κυρίως για την κοπή μεγάλων ή μακριών απορριμμάτων μετάλλων. Έχει χωρητικότητα 4-6 φορές ανά λεπτό για ψαλίδισμα απορριμμάτων μετάλλων.

Αυτό το ψαλίδι κοπής μετάλλων υιοθετεί ψυχρή κοπή, κόβοντας παλιοσίδερα σε 20-30 cm και η απόδοση κυμαίνεται από 2,5-30 τόνους ανά ώρα.

Η υδραυλική ψαλίδα μετάλλων είναι πάντα εξοπλισμένη με μεταφορέα για τροφοδοσία παλιοσίδερων. Είναι κατάλληλο για διάφορα σχήματα σκραπ χάλυβα, σκραπ σιδήρου, ερειπωμένα βαρέλια βενζίνης και διάφορα μεταλλικά δομικά μέρη.

Επιπλέον, μπορεί να χειριστεί μεγάλες ποσότητες σκραπ και είναι επίσης πολύ φιλικό προς το περιβάλλον.

Έτσι, η ψαλίδα παλιοσίδερων χρησιμοποιείται ευρέως σε διάφορες μονάδες επεξεργασίας ανακύκλωσης μετάλλων, χώρους αποσυναρμολόγησης παλιοσίδερων αυτοκινήτων, βιομηχανίες τήξης και χύτευσης κ.λπ. Εάν ενδιαφέρεστε, καλώς ήλθατε να επικοινωνήσετε μαζί μας για περισσότερες λεπτομέρειες!

Πλεονεκτήματα της υδραυλικής ψαλίδας

- Αυτό το μηχάνημα υιοθετεί υδραυλική πίεση για εργασία, χαμηλό θόρυβο, σταθερή λειτουργία και μεγάλη διάρκεια ζωής.

- Η μηχανή διάτμησης μετάλλων Shuliy υιοθετεί ηλεκτρικό έλεγχο, εύκολο και ασφαλές στη χρήση.

- Το μηχάνημα είναι η ισχυρότερη δύναμη διάτμησης από το Shuliy, το οποίο μπορεί να χειριστεί θραύσματα μετάλλων βαρέως τύπου. Η χωρητικότητά του είναι επίσης πολύ ισχυρή.

- Διαθέτει ένα ευρύ φάσμα επεξεργασίας απορριμμάτων μετάλλων, όπως ράβδους κατασκευών, κελύφη αυτοκινήτων. Έχει πολύ δυνατή πρακτικότητα.

- Υπάρχουν διάφορα μοντέλα μηχανημάτων και η απόδοση κυμαίνεται από 3t έως 250t.

- Το μέγεθος των τελικών προϊόντων μπορεί να ρυθμιστεί. Σε γενικές γραμμές, το μέγεθος του τελικού προϊόντος είναι 20-30 cm.

Τεχνικές παράμετροι διάτμησης μετάλλων βαρέως τύπου

| Μοντέλο | SLY-200T | SLY-400T | SLY-600T | SLY-800T | SLY-1000T | SLY-1250T |

| Μέγ. δύναμη κοπής (t) | 200 | 400 | 600 | 800 | 1000 | 1250 |

| Πίεση συστήματος (Mpa) | ≤25 | ≤25 | ≤25 | ≤25 | ≤25 | ≤25 |

| Μέγεθος κάδου (mm) | 700*1600*2300 | 5000*1300*500 | 5500*1500*700 | 6000*1700*800 | 6000*1900*1000 | 8000*2100*1500 |

| Μήκος λεπίδας (mm) | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 |

| Χωρητικότητα (t/h) | 2.5-3 | 4-5 | 8-10 | 15-20 | 20-25 | 25-30 |

| Διατμητική δύναμη (χρόνοι/λεπτό) | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 |

| Ισχύς (kW) | 2*18.5 | 2*45 | 3*45 | 4*45 | 5*45 | 6*45 |

| Βάρος (t) | 11 | 19 | 30 | 38 | 60 | 88 |

Διαθέτουμε διάφορα είδη υδραυλικών ψαλιδιών μετάλλων προς πώληση, και η χωρητικότητα είναι 2,5-30 τόνοι την ώρα. Αν ψάχνετε για μια λύση ανακύκλωσης μεταλλικών απορριμμάτων, μη διστάσετε να επικοινωνήσετε μαζί μας. Θα σας παρέχουμε τις καλύτερες προτάσεις.

Για παράδειγμα, εάν θέλετε να κόψετε απορρίμματα χάλυβα οικοδομής χωρητικότητας 4-10 τόνων την ώρα. Επίσης, ο προϋπολογισμός σας είναι επαρκής. Τότε το ψαλίδι SLY-800T θα είναι η καλύτερη επιλογή για εσάς.

Εάν θέλετε μια λεπτομερή λύση, καλώς ήρθατε να επικοινωνήσετε μαζί μας ανά πάσα στιγμή για περισσότερα!

Εφαρμόσιμες πρώτες ύλες & εφαρμογές υδραυλικής ψαλίδας

Αυτή η μηχανή κοπής λαμαρίνας είναι κυρίως κατάλληλη για την κοπή διαφόρων θραυσμάτων μετάλλων, όπως:

Συμπαγής σιδηρομεταλλεύματα, ελαφρύς και λεπτός χάλυβας για παλιοσίδερα, κελύφη αυτοκινήτων για παλιοσίδερα, ογκώδεις ελαφρές μεταλλικές κατασκευές από χάλυβα, χάλυβας για παλιοσίδερα για παραγωγή και οικιακή χρήση, διάφορα πλαστικά μη σιδηρούχα μέταλλα (ανοξείδωτος χάλυβας, κράματα αλουμινίου, υλικά χαλκού), απορρίμματα χάλυβα από κατασκευές, μεγάλες ακανόνιστες χαλύβδινες κατασκευές, χαλύβδινες σωλήνες, χαλύβδινες πλάκες, κανάλια χάλυβα, I-δοκοί, χάλυβας ράβδων, κ.λπ.

Μετά το κούρεμα, είναι για εύκολη μεταφορά και κατάλληλο για δεματοποίηση με συμπίεση σε γόμωση κλιβάνου.

Το ηλεκτρικό ψαλίδι μετάλλων Shuliy είναι ιδανικός εξοπλισμός επεξεργασίας για:

- Χαλυβουργεία

- Βιομηχανία τήξης μη σιδηρούχων μετάλλων

- Βιομηχανία χύτευσης ακριβείας

- Κατασκευαστές πρώτων υλών

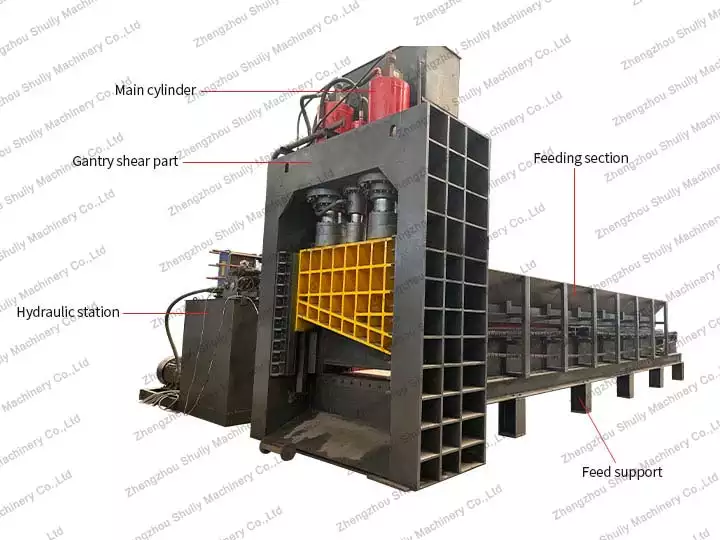

Δομή της βαρέως τύπου ψαλίδας μεταλλικών σκελετών

Αυτό το μηχάνημα είναι κατασκευασμένο από κάδο, κεφαλή και κόφτη.

- Αποθήκη: αποθηκεύστε όλα τα είδη μετάλλων. Μερικές φορές χρειάζεστε τον φορτωτή για τη φόρτωση παλιοσίδερων, βολικό και γρήγορο.

- Κεφαλή μηχανής: κατακόρυφο πλαίσιο με υδραυλικό μοχλό από πάνω, που πιέζεται προς τα κάτω κατά την εργασία.

- Λεπίδα: σημαντικό εργαλείο για την κοπή μεταλλικών θραυσμάτων.

- Τα διαφορετικά μοντέλα μηχανών έχουν διαφορετικές λεπίδες.

- Οι λεπίδες ανήκουν στα φθαρμένα μέρη, τα οποία μπορούν να εξοπλιστούν κατάλληλα με μερικά ακόμη σετ.

Πώς λειτουργεί η μηχανή κοπής μετάλλων Shuliy;

Η ροή εργασίας του μηχανήματος μπορεί να περιγραφεί ως απλή.

- Αρχικά, χρησιμοποιήστε τη μηχανή φόρτωσης για να φορτώσετε το υλικό.

- Όταν τα μεταλλικά θραύσματα φθάσουν σε μια ορισμένη ποσότητα, η φόρτωση μπορεί να σταματήσει και η πόρτα του κάδου μπορεί να κλείσει.

- Στη συνέχεια, η υδραυλική ράβδος αρχίζει να λειτουργεί.

- Υπάρχει ένας υδραυλικός μοχλός στο πίσω μέρος του κάδου, που σπρώχνει τα μεταλλικά θραύσματα προς τα εμπρός.

- Ο υδραυλικός μοχλός στην κεφαλή του μηχανήματος είναι υπεύθυνος για την πίεση του υλικού.

- Τέλος, ο κόφτης πέφτει για να κόψει το σκραπ, και η όλη διαδικασία ολοκληρώνεται. Στη συνέχεια επαναλάβετε όλη τη διαδικασία.

Γιατί να κόβουμε παλιοσίδερα για ανακύκλωση;

- Υψηλότερη τιμή πώλησης. Μετά την κοπή, μπορεί να συσκευαστεί και να μεταφερθεί εύκολα. Όταν πωλείται, η πυκνότητα είναι μεγαλύτερη και η τιμή θα είναι υψηλότερη.

- Περαιτέρω επεξεργασία και αξιοποίηση. Μετά το κούρεμα, διάφορα απόβλητα μετάλλων μπορούν να τεθούν σε εργοστάσια επεξεργασίας μετάλλων, μεταλλουργεία κ.λπ. Είναι για περαιτέρω επεξεργασία για να δημιουργηθούν περισσότερα κέρδη.

- Βολική ανακύκλωση σκραπ. Εάν τα απόβλητα δεν κουρευτούν, θα είναι δύσκολο να επεξεργαστούν και να ανακυκλωθούν. Η κοπή απλώς λύνει αυτό το πρόβλημα.

Προφυλάξεις κατά τη λειτουργία και αντικατάσταση λεπίδων

Διαβάστε αυτό το άρθρο για να μάθετε περισσότερες λεπτομέρειες: Πώς να χρησιμοποιήσετε και να αλλάξετε τις λεπίδες ενός ψαλιδιού γκιλοτίνας για παλιοσίδερα;

Τι θα λέγατε για την τιμή διάτμησης βαρέος τύπου;

Η τιμή του μηχανήματος είναι ένα από τα πιο σημαντικά πράγματα που πρέπει να λάβετε υπόψη και επηρεάζεται κυρίως από τα ακόλουθα:

- Διατμητική δύναμη και διατμητική ικανότητα. Όσο μεγαλύτερη είναι η δύναμη διάτμησης, τόσο περισσότερους τύπους και μεγέθη μεταλλικών απορριμμάτων μπορεί να χειριστεί ο εξοπλισμός. Κατά συνέπεια, η τιμή θα είναι υψηλότερη.

- Υδραυλικό σύστημα και ισχύς κινητήρα. Υδραυλικά συστήματα και κινητήρες υψηλότερης ισχύος παρέχουν μεγαλύτερη δύναμη διάτμησης και υψηλότερη απόδοση, αλλά και αυξάνουν το κόστος εξοπλισμού.

- Ποιότητα και ζωή λεπίδας. Η χρήση υλικών υψηλής σκληρότητας, υψηλής αντοχής στη φθορά από λεπίδες κοστίζει περισσότερο. Ωστόσο, μπορεί να παρατείνει σημαντικά τη διάρκεια ζωής του εξοπλισμού και να μειώσει το κόστος συντήρησης.

- Μάρκα και εξυπηρέτηση μετά την πώληση. Τα ψαλίδια σκελετών διάσημων εμπορικών σημάτων έχουν συνήθως εγγυημένη ποιότητα και άψογη εξυπηρέτηση μετά την πώληση, επομένως η τιμή είναι σχετικά υψηλή.

- Εξατομικευμένη ζήτηση. Εάν θέλετε να προσαρμόσετε το μηχάνημα (όπως ειδικό μέγεθος, επιπλέον χαρακτηριστικά ή βελτιωμένη αντοχή), η τιμή του μηχανήματος θα είναι υψηλότερη από το τυπικό μοντέλο.

Επιτυχημένη υπόθεση: υδραυλική ψαλίδα μετάλλων προς πώληση στο Μπαχρέιν

Τον Ιούλιο του τρέχοντος έτους, ένας πελάτης από το Μπαχρέιν μας ζήτησε πληροφορίες σχετικά με το ψαλίδι. Σύμφωνα με το αίτημά του, ο διευθυντής πωλήσεών μας του συνέστησε αυτό το ψαλίδι.

Όχι μόνο μπορεί να χειριστεί μια μεγάλη ποσότητα απορριμμάτων μετάλλου, αλλά και η δύναμη διάτμησης είναι η ισχυρότερη που μπορεί να χειριστεί. Το μηχάνημα είναι σταθερό και μπορεί επίσης να χρησιμοποιηθεί για μεγάλο χρονικό διάστημα.

Αφού κατανόησε το μηχάνημα, αυτός ο πελάτης από το Μπαχρέιν ήταν πολύ χαρούμενος και υπογράψαμε μια συμφωνία. Μιλήσαμε και για αποστολή της μηχανής δια θαλάσσης στον τόπο του.

Περαιτέρω διάλυμα ανακύκλωσης απορριμμάτων μετάλλων

Μετά το ψαλίδισμα, μπορείτε να συμπιέσετε περαιτέρω τα απόβλητα σε κύβους μεταλλικών απορριμμάτων με το οριζόντιο πρέσα μετάλλων.

Αναζητάτε μια αποτελεσματική λύση ανακύκλωσης μετάλλων; Εάν ναι, επικοινωνήστε μαζί μας τώρα και θα παρέχουμε την καλύτερη λύση προς όφελος της επιχείρησής σας.