Υδραυλική μηχανή διάτμησης μετάλλων | Διάτμηση αλιγάτορα

| Μοντέλο | SL-1200 |

| Τυπική δύναμη διάτμησης | 250 Τ |

| Μοτέρ | 4-22 kw |

| Δυναμικό | 380v/50Hz |

| Αντλία λαδιού | 80*1 |

| Μήκος λεπίδας κοπής | 1200 χλστ |

| Τρόπος ελέγχου | αυτόματη/χειροκίνητη λειτουργία |

| Αριθμός κοπής ανά λεπτό | 8-12 |

Τώρα μπορείτε να ρωτήσετε τους διαχειριστές του έργου μας για τεχνικές λεπτομέρειες

Η υδραυλική μηχανή κοπής μετάλλων Shuliy χρησιμοποιείται κυρίως για την κοπή διαφόρων απορριμμάτων μεταλλικών φύλλων, σωλήνων χάλυβα, πλακών χάλυβα κ.λπ. σε κομμάτια για ανακύκλωση. Μπορεί να κόψει απορρίμματα 8-12 φορές ανά λεπτό.

Αυτή η ψαλίδα αλιγάτορα μπορεί να εξοπλίσει τον μεταφορέα για τροφοδοσία απορριμμάτων μετάλλων. Διαθέτει χειροκίνητους και αυτόματους τύπους ελέγχου. Όταν χρησιμοποιείτε αυτή τη μηχανή κοπής θραυσμάτων μετάλλων για την κοπή παλιοσίδερων, το μήκος κοπής μπορεί να ρυθμιστεί ελεύθερα.

Χρησιμοποιείται κυρίως στη βιομηχανία ανακύκλωσης και επεξεργασίας απορριμμάτων, καθώς και σε μικρές και μεσαίες χαλυβουργίες. Αν ψάχνετε για μια λύση απορριμμάτων μετάλλων, αυτή η μηχανή είναι η ιδανική επιλογή.

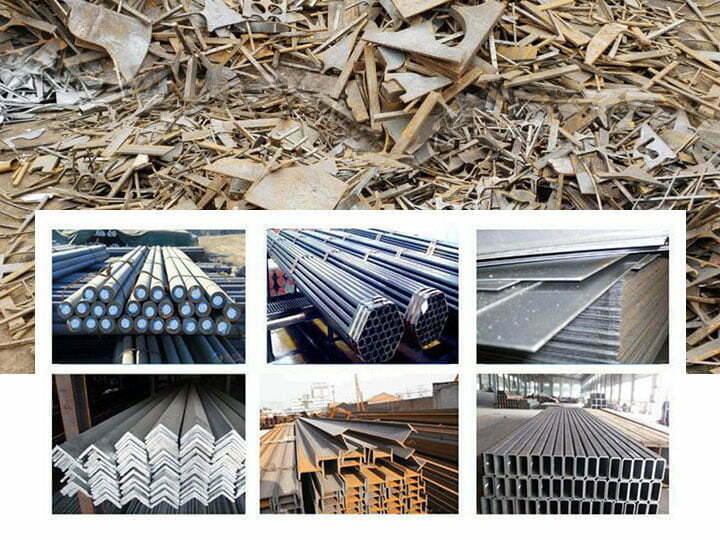

Ποια απόβλητα μετάλλων μπορούν να κοπούν;

Αυτός ο τύπος σιαγόνας μηχανής κοπής παλιοσίδερων είναι κατάλληλος για την κοπή διαφόρων απορριμμάτων μετάλλων, όπως:

Χάλυβας καναλιών, παλιοσίδερα, τετραγωνικός χάλυβας, παλιοσίδερα κατασκευών, ράβδοι οπλισμού, γωνιακός χάλυβας, διπλός δοκός, σωλήνας χάλυβα, φύλλα σιδήρου, χυτοσίδηρος, χαλύβδινες πλάκες, έγχρωμες κεραμίδες χάλυβα, μεταλλικά απορρίμματα, φύλλα κράματος αλουμινίου, πλάκες χαλκού, φύλλα παλιοσιδήρου, κουτιά αλουμινίου, μπάρες παλιοσιδήρου, πλάκες αλουμινίου, πλάκες σιδήρου, στρογγυλός χάλυβας, σασί αυτοκινήτων, δεξαμενές αλουμινίου, δεξαμενές βενζίνης, δεξαμενές βαφής, δεξαμενές φυσικού αερίου, κ.λπ.

Εφαρμογές υδραυλικής διάτμησης αλιγάτορα

Αφού μάθετε τι μπορεί να γίνει η κοπή παλιοσίδερων, τώρα ήρθε η ώρα να δούμε πού μπορεί να χρησιμοποιηθεί αυτός ο εξοπλισμός.

Αυτή η υδραυλική μηχανή διάτμησης μετάλλων χρησιμοποιείται κυρίως σε:

- Χαλυβουργεία

- Εταιρείες επεξεργασίας απορριμμάτων χάλυβα

- Εγκαταστάσεις επεξεργασίας ανακύκλωσης απορριμμάτων μετάλλων

- Εγκαταστάσεις αποσυναρμολόγησης σκραπ αυτοκινήτων

- Βιομηχανίες τήξης και χύτευσης χάλυβα

Χαρακτηριστικά της υδραυλικής μηχανής διάτμησης μετάλλων

- Μήκη λεπίδας κοπής σε 400mm, 600mm, 700mm, 800mm, 1000mm και 1200mm. Αυτό το ψαλίδι αλιγάτορα έχει διάφορες προδιαγραφές λεπίδας κοπής, παρέχοντας στους πελάτες περισσότερες επιλογές.

- Η υδραυλική μηχανή διάτμησης μετάλλων με μήκος λεπίδας κοπής άνω των 700 mm είναι ιδιαίτερα κατάλληλη για την κοπή αυτοκινήτων που έχουν υποστεί σκραπ.

- Λίγοι περιορισμοί για τις πρώτες ύλες για κοπή. Η μέθοδος διάτμησης δεν είναι αυστηρή με το μέγεθος τροφοδοσίας των απορριμμάτων μετάλλων. Έτσι, υπάρχουν λιγότεροι περιορισμοί.

- Διατμητική δύναμη από 63 τόνους έως 400 τόνους σε 8 βαθμούς. Η μηχανή κοπής τύπου κροκόδειλου Shuliy έχει διάφορους διαθέσιμους τύπους, που είναι ένα ευρύ φάσμα επιλογών για τους πελάτες.

- Πολλαπλές επιλογές συστημάτων ισχύος. Αυτό το μηχάνημα μπορεί να χρησιμοποιήσει έναν ηλεκτρικό κινητήρα ή έναν κινητήρα ντίζελ ως σύστημα ισχύος. Όπου δεν υπάρχει τροφοδοσία, ο κινητήρας ντίζελ μπορεί να χρησιμοποιηθεί ως ισχύς.

Παράμετροι της υδραυλικής μηχανής κοπής μετάλλων

| Μοντέλο | SL-1200 |

| Τυπική δύναμη διάτμησης | 250 τ |

| Μοτέρ | 4-22 kw |

| Δυναμικό | 380V/50Hz |

| Αντλία λαδιού | 80*1 |

| Μήκος λεπίδας κοπής | 1200 χλστ |

| Τρόπος ελέγχου | Αυτόματη/χειροκίνητη λειτουργία |

| Αριθμός κοπής ανά λεπτό | 8-12 φορές |

Αυτή η υδραυλική μηχανή διάτμησης μετάλλων SL-1200 έχει ισχυρή ικανότητα διάτμησης, κατάλληλη για κάθε είδους επεξεργασία διάτμησης υλικών παλιοσίδερων.

Μπορούμε να προσαρμόσουμε την τάση, το μήκος της λεπίδας, την πίεση κ.λπ. Η Shuliy μπορεί να τα σχεδιάσει για να ικανοποιήσει τις απαιτήσεις σας.

Εάν ενδιαφέρεστε για την ανακύκλωση απορριμμάτων μετάλλων, καλώς ήρθατε να επικοινωνήσετε μαζί μας για περισσότερες λεπτομέρειες!

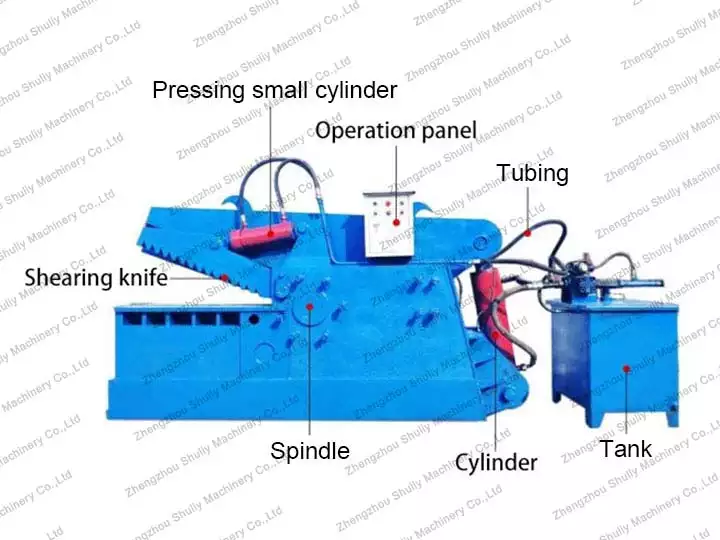

Δομή μηχανής κοπής παλιοσίδερων

Η δομή της υδραυλικής μηχανής διάτμησης μετάλλων περιλαμβάνει κυρίως το πλαίσιο, την κεφαλή διάτμησης, το νύχι συμπίεσης, τον κύλινδρο δράσης της κεφαλής διάτμησης, τον κύλινδρο δράσης με νύχια πίεσης και τη συσκευή παροχής υδραυλικού λαδιού.

Από τη σχεδίασή του, είναι σαφές ότι αυτό το υδραυλικό ψαλίδι μετάλλων έχει την άνετη και απλή λειτουργία.

Το στόμιο διάτμησης μπορεί να κόψει και να σταματήσει σε οποιαδήποτε θέση κατά τη διάρκεια της διαδικασίας εργασίας. Ανάλογα με το μέγεθος του υλικού, αυθαίρετος έλεγχος του μεγέθους του στομίου διάτμησης. Αυτό μπορεί να επιτύχει υψηλή απόδοση εργασίας.

Αρχή λειτουργίας της διάτμησης αλιγάτορα τύπου κροκοδείλου

Αυτό το μηχάνημα λειτουργεί μέσω ενός υδραυλικού συστήματος.

Όταν η διάτμηση είναι σε εξέλιξη, ο σταθμός υδραυλικής αντλίας (πηγή εξόδου ισχύος) τροφοδοτεί λάδι στον κύλινδρο πίεσης για να σπρώξει το συρόμενο μαχαίρι πίεσης στην κάτω έδρα του μαχαιριού. Το υλικό είναι σταθερό και συμπιεσμένο.

Στη συνέχεια, ο σταθμός υδραυλικής αντλίας τροφοδοτεί λάδι στον κύλινδρο διάτμησης για να κάνει το μαχαίρι διάτμησης να κινηθεί προς τα κάτω για να ολοκληρώσει το βήμα διάτμησης.

Μετά την ολοκλήρωση της διάτμησης, ο σταθμός υδραυλικής αντλίας ολοκληρώνει τη διαδρομή επιστροφής που προκαλείται από την παλινδρόμηση του υδραυλικού λαδιού του κυλίνδρου διάτμησης και του κυλίνδρου πίεσης.

Τι λέτε για την τιμή υδραυλικής διάτμησης μετάλλων;

Η τιμή της υδραυλικής διάτμησης μετάλλων Shuliy ποικίλλει ανάλογα με διάφορους παράγοντες, όπως το μοντέλο του εξοπλισμού, τη δύναμη διάτμησης, τη διαμόρφωση, τη μάρκα και την εξυπηρέτηση μετά την πώληση.

- Γενικά, όσο μεγαλύτερη είναι η δύναμη διάτμησης, όσο μεγαλύτερη είναι η διαμόρφωση της υδραυλικής διάτμησης, η τιμή της είναι αντίστοιχα υψηλότερη.

- Όταν αγοράζετε υδραυλικό ψαλίδι μετάλλων, εκτός από την εστίαση στην τιμή, πρέπει επίσης να λάβετε υπόψη την ποιότητα και την απόδοση του εξοπλισμού.

- Η επιλογή μιας μάρκας με καλή φήμη και εγγύηση εξυπηρέτησης μετά την πώληση, όπως η Shuliy, μπορεί να διασφαλίσει ότι ο εξοπλισμός είναι πιο αξιόπιστος και αποτελεσματικός στη διαδικασία χρήσης.

Εάν πρέπει να γνωρίζετε τη συγκεκριμένη τιμή υδραυλικής διάτμησης μετάλλων, μπορείτε να λάβετε μια λεπτομερή προσφορά επικοινωνώντας με την ομάδα πωλήσεών μας. Θα προτείνουμε ένα κατάλληλο μοντέλο και θα παρέχουμε το καλύτερο σχέδιο τιμής σύμφωνα με τις συγκεκριμένες ανάγκες σας.

Οδηγοί ασφαλούς λειτουργίας για υδραυλική μηχανή διάτμησης μετάλλων

- Ο εξοπλισμός κοπής μετάλλων θα λειτουργεί από ειδικό προσωπικό.

- Πριν χρησιμοποιήσετε αυτό το ψαλίδι αλιγάτορα, ελέγξτε προσεκτικά εάν όλα τα μέρη του μηχανήματος είναι κανονικά και εάν οι σύνδεσμοι είναι σταθεροί.

- Η μηχανή κοπής μετάλλων απαγορεύεται να κόβει:

- Μη ανοπτημένα εξαρτήματα από χάλυβα, μέρη από χυτοσίδηρο, μαλακά μεταλλικά μέρη, λεπτά μεταλλικά υλικά, υλικά με μήκη μικρότερα από 100 mm και απορρίμματα μετάλλων που υπερβαίνουν το μήκος του ψαλιδιού.

- Κατά τη διάρκεια της επέμβασης, το ανθρώπινο σώμα δεν επιτρέπεται να πλησιάσει το τμήμα μετάδοσης και την άκρη του μαχαιριού του εξοπλισμού.

- Πρέπει να δίνεται προσοχή στην ασφάλεια του περιβάλλοντος προσωπικού για να αποφευχθεί η παραμόρφωση του υλικού και η πρόκληση βλάβης στους ανθρώπους.

- Όταν κόβετε, προσπαθήστε να κόψετε το υλικό κοντά στο εσωτερικό του μαχαιριού.

- Κατά την κοπή κοντών υλικών, δεν επιτρέπεται η χρήση τεμαχίων χειρός για την τροφοδοσία υλικών. Μπορείτε να τροφοδοτήσετε υλικά με σφιγκτήρα.

- Όταν ο εξοπλισμός λειτουργεί, ο χειριστής δεν πρέπει να εγκαταλείψει τη θέση χωρίς άδεια.

- Όταν οι εργασίες ολοκληρωθούν ή εγκαταλείψουν προσωρινά, η παροχή ρεύματος θα διακοπεί.

- Ταυτόχρονα, όταν το μηχάνημα λειτουργεί, δεν επιτρέπεται η επισκευή ή η επαφή με τα κινούμενα μέρη με τα χέρια. Απαγορεύεται αυστηρά η πίεση των υλικών στο κουτί υλικού με τα χέρια ή τα πόδια.

- Τα λιπαντικά μέρη της μηχανής πρέπει να γεμίζονται με λιπαντικό λάδι τουλάχιστον μία φορά ανά βάρδια όπως απαιτείται.

Νέου τύπου μικρή υδραυλική μηχανή διάτμησης αλιγάτορα

Αυτός ο νέος τύπος υδραυλικής μηχανής διάτμησης μετάλλων σχεδιάστηκε πρόσφατα από το εργοστάσιό μας. Αυτό το ψαλίδι παλιοσίδερων είναι κατάλληλο για υλικά που δεν μπορούν να κοπούν πολύ χοντρά, όπως πλαστικά.

μικρή μηχανή κοπής μετάλλων

Η μικρή μηχανή κοπής τύπου κροκόδειλου έχει τα πλεονεκτήματα της οικονομικής απόδοσης, του ελαφρού βάρους, της εύκολης κίνησης και του μικρού αποτυπώματος. Είναι ιδανικό για μικρές ή νεοσύστατες επιχειρήσεις.

Επικοινωνήστε μαζί μας για περισσότερες λεπτομέρειες του μηχανήματος!

Ως επαγγελματίας κατασκευαστής εξοπλισμού ανακύκλωσης μετάλλων, διαθέτουμε επίσης μεταλλική ψαλίδα τύπου κεφαλής τίγρης, γερανοφόρο ψαλίδα κοπής κ.λπ., που μπορούν να καλύψουν τις διαφορετικές σας ανάγκες.

Αν ψάχνετε για αποτελεσματικές λύσεις για την ανακύκλωση απορριμμάτων μετάλλων, επικοινωνήστε μαζί μας τώρα. Η ομάδα πωλήσεών μας θα σας παρέχει την καλύτερη λύση σύμφωνα με τις ανάγκες σας.