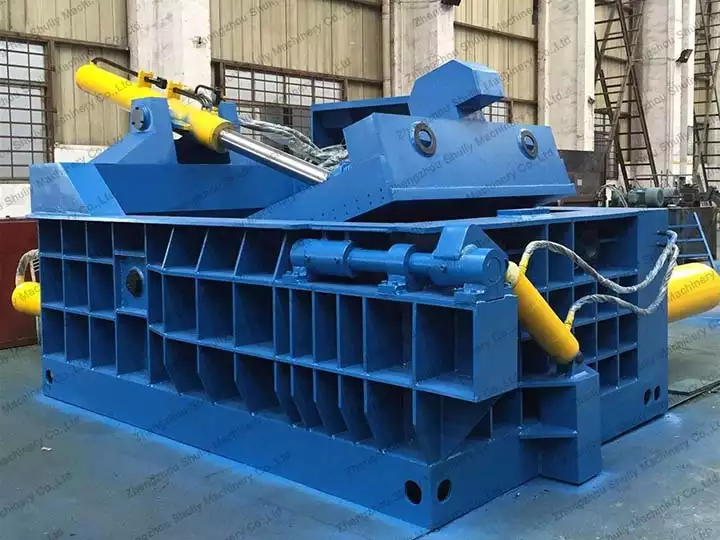

Hydraulische Altmetallballenpresse für Abfallballenpresse

Metallverdichter | Ballenpresse für Metallschrott

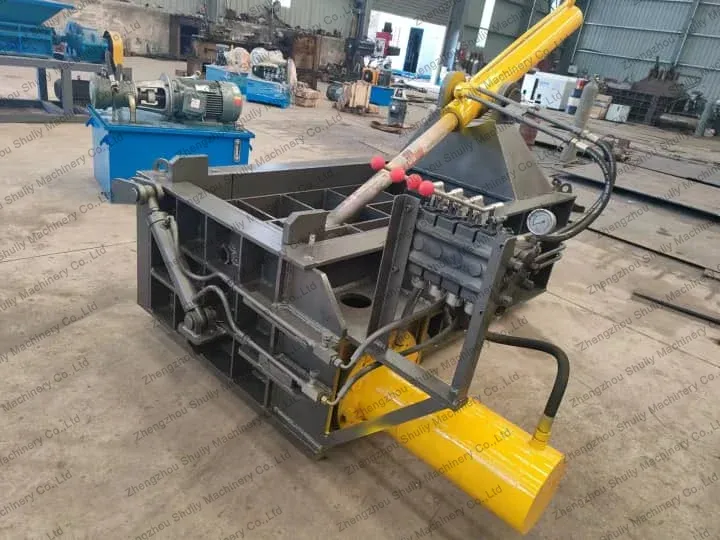

Modell: SL-Y81-125

Druck: 125t

Größe des Pressbehälters: 1200 x 800 x 500 mm

Ballengröße: 30*30cm

Presszeit: 10s

Leistung: 15 kW

Funktionen: Anpassung

Service: Kundendienst, Online-Beratung usw

Die horizontale Schrottmetallballenpresse (auch bekannt als Eisenballenpresse, Dosenballenpresse, Stahlschrottballenpresse und Aluminiumdosenballenpresse) wird hauptsächlich verwendet, um verschiedene Metallschrotte, Stahlspäne, Stahlschrott, Aluminiumschrott, Kupferschrott usw. zu dichten Schrottmetallballen für das Recycling und zur Gewinnerzielung zu verdichten.

Die Form des Endprodukts kann zylindrisch, rechteckig, würfelförmig, hexagonal und andere Mehrprismenformen sein. Die Blockgrößen sind unterschiedlich, wie z.B. 30*30cm, 35*35cm, 40*40cm usw.

Dieser Metallverdichter kann entweder den Elektromotor oder einen Dieselmotor als Antrieb verwenden und arbeitet mit dem hydraulischen System. Der hydraulische Druck kann entsprechend den tatsächlichen Pressanforderungen eines bestimmten Materials angepasst werden.

Aufgrund seiner hohen Effizienz, Anpassungsfähigkeit und geringeren Wartung verkauft sich unsere Metallpressmaschine im Ausland sehr gut, zum Beispiel in Malaysia, Kuwait, den Philippinen, Afghanistan und so weiter. Wenn Sie interessiert sind, kontaktieren Sie uns jederzeit gerne!

Was ist eine Schrottballenpresse?

Dieser Schrottverdichter kann in großem Umfang in mittelgroßen und großen Recyclinganlagen für Metallressourcen und in Fabriken zur Herstellung von Metallprodukten eingesetzt werden.

Die hydraulische Schrottballenpresse nutzt die Mehrfachstärke ihres Hydrauliksystems, um Metallabfälle unregelmäßiger Form und Größe in kompakte Säulen zu pressen. Nach dem Ballenpressen lassen sich diese Schrottballen leicht transportieren und in den Behältern lagern, wodurch viel Platz gespart wird.

Technische Parameter der zum Verkauf stehenden Schrottballenpresse

| Ausstattungsmodell | Druck (Tonne) | Pressbehältergröße (mm) | Ballengröße (cm) | Presszeit (s) | Leistung (kW) |

| SL-Y81-125 | 125 | 1200*800*500 | 30*30 | 100 | 15 |

| SL-Y81-135 | 135 | 1200*1000*600 | 30*30 | 110 | 18.5 |

| SL-Y81-160 | 160 | 1200*1000*600 | 35*35 | 110 | 18.5 |

| SL-Y81-180 | 180 | 1600*1200*800 | 40*40 | 130 | 22 |

| SL-Y81-200 | 200 | 1600*1200*800 | 50*50 | 140 | 22+15 |

| SL-Y81-250 | 250 | 2000*1750*1000 | 50*50 | 150 | 44 |

| SL-Y81-315 | 315 | 2500*2000*1200 | 60*60 | 160 | 60 |

| SL-Y81-400 | 100 | 3000*2500*1200 | 60*60 | 170 | 90 |

Anwendungen von hydraulischen Schrottpressen

Der Schrottpressen-Baler kann verschiedene Abfallmetallprodukte unter normalen Bedingungen pressen. Die Materialien sind:

- Eisenmetallschrott

- Schrott Eisen und Schrott Stahl

- Eisenbleche und leichte/dünne Eisenmaterialien

- Roheisenblöcke

- Autokarosserien und Automobilrahmen

- Eisenfässer und gebrauchte Fahrräder

- Nichteisenmetallschrott

- Schrottkupferblöcke

- Aluminiumschrottflocken

- Aluminiumlegierungsprofile

- Farbenbehälter & Aluminiumdosen

- Farbeimer

- Bierdosen und Getränkedosen

- Blechdosen

- Leichtbaureste

- Farbstahlplatten

- Dünne Eisenbleche

Die Schrottmetallballenpresse eignet sich für verschiedene große, mittlere und kleine Stahlwerke, die Abfallmetall-Recyclingindustrie und die Nichteisenmetall-Schmelzindustrie. Die endgültige Produktform kann Würfel, Zylinder, Achtecke, Rechtecke, Sechsecke usw. sein.

Vorteile der hydraulischen Altmetallballenpresse

- Tolles Design der Altmetall-Ballenpresse, platzsparend und bequemer für den Transport.

- Der nach dem Pressen entstandene Metallschrott ist dichter und kann zu einem höheren Preis verkauft werden.

- Unsere Metallschrott-Ballenpresse kann für Schrott verwendet werden, wodurch wiederum Einnahmen für die Fabrik erzielt werden können.

- Es gibt zwei Arten von Betriebssystemen: eines ist vollautomatisch und das andere ist ein manueller Betrieb (Bedienung erfolgt über einen Handhebel).

- Die Platte kann basierend auf dem Original zur Maschine hinzugefügt werden, sodass die Maschine verschleißfester ist und eine längere Lebensdauer hat.

- Sie können auch die Klingen hinzufügen, um das Verpacken großer Materialien zu vereinfachen.

Wie funktioniert die Ballenpresse für Metallschrott?

Metallische Werkstoffe haben die Eigenschaft, sich plastisch zu verformen. Der hydraulische Druck der horizontalen Metallballenpresse kann den Metallmaterialien eine ausreichende äußere Kraft verleihen, die sich zusammenballen und eine dauerhafte Verformung bewirken kann, wodurch ein kompakter, fester Block entsteht.

Wenn die hydraulische Schrottballenpresse arbeitet, können wir mit dem Greifer die zu verpackenden Materialien in die Kiste des Verpackers legen. Öffnen Sie anschließend das Steuerventil des Hydraulikzylinders der Maschine. Die hydraulische Metallballenpresse selbst verfügt über drei aufeinander aufbauende Hydraulikdrücke, die Metallmaterialien schnell zu Säulen komprimieren können.

Wartungstipps für die Altmetallballenpresse

- Reinigen Sie den Behälter der Metallballenpresse jede Woche von Abfällen oder Schmutz.

- Reinigen und schmieren Sie einmal im Monat den Schieber, das Mittelmesser und den vorderen Auswerfer.

- Tragen Sie alle drei Monate Schmiermittel auf alle Lager der Maschine auf.

- Füllen Sie das Hydrauliköl im Öltank der Metallballenpresse regelmäßig alle zwei Jahre nach.

- Jedes Mal, wenn Sie Hydrauliköl hinzufügen, sollte es angemessen sein. Denken Sie daran, nicht zu viel hinzuzufügen, um Fehlfunktionen des Mikroschalters aufgrund von Öleinlagerungen zu vermeiden.

Erfolgreiche Fälle von Schrottballenpressen zum Verkauf auf der ganzen Welt

Erfolgreicher Fall: Die nach Irak exportierte horizontale Metallballenpresse

Der irakische Kunde verfügte über eine große Ansammlung von Metallschrott und wollte dieses Material effizient entsorgen, vorzugsweise so, dass ein sekundäres Einkommen erzielt werden konnte. Deshalb machte sich dieser Kunde auf die Suche nach einer Metallballenpresse und kontaktierte uns, nachdem er unsere Maschinen gesehen hatte. Nachdem er von unseren Maschinen erfahren hatte, war er sehr zufrieden und hatte das Gefühl, dass dies die Maschine war, die er wollte. Daher wurde der Vertrag sofort unterzeichnet. Hier ist ein Bild unserer Lieferung zum Hafen.

SL-125 hydraulische Schrottmetallballenpresse nach Afghanistan verkauft

Unser Metallverdichter wurde erfolgreich an ein großes Altmetallrecyclingunternehmen in Afghanistan verkauft. Aufgrund der hervorragenden Stabilität und Haltbarkeit ist das Unternehmen in der Lage, alle Arten von Altmetall schnell zu verarbeiten. Das Unternehmen hat die Effizienz der Altmetallverarbeitung deutlich verbessert, die Transportkosten gesenkt und die Effektivität der Ressourcenrückgewinnung erhöht.

SL-125 Metallkomprimierer an Malaysia geliefert

In Malaysia haben wir eine Schrottballenpresse für ein auf Metallrecycling spezialisiertes Unternehmen bereitgestellt. Wir haben die Metallballenpresse mit 15 kW Leistung und einer Ballengröße von 30*30 cm mit der Seitenschubballenmethode für Malaysia angepasst.

Kontaktieren Sie uns für ein Angebot!

Interessiert daran, wie schnell Sie Schrottmetall recyceln können? Wenn ja, kontaktieren Sie uns! Wir bieten Ihnen die optimale Lösung und das beste Angebot entsprechend Ihren Bedürfnissen.