Wie verwendet und wechselt man die Klingen einer Altmetall-Tafelschere?

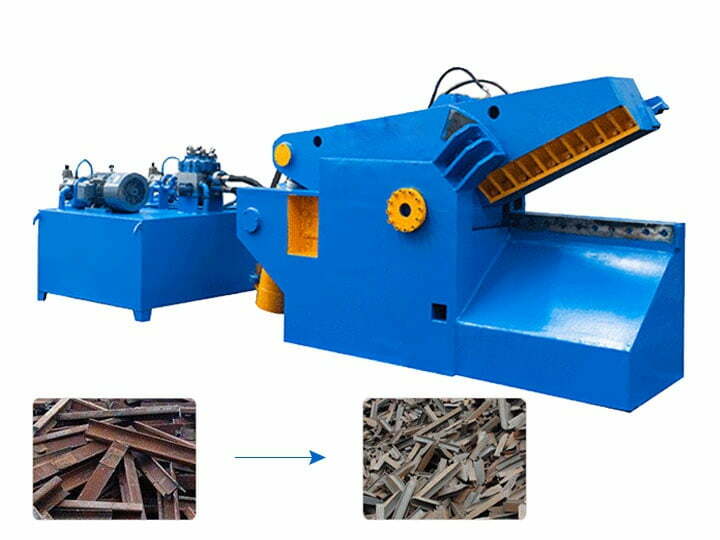

Als groß angelegte hydraulische Scher- und Schneidausrüstung ist die Tafelschere für Altmetall (Portalschermaschine) besteht hauptsächlich aus Portal, Silo, Hydrauliksystem usw. Die hydraulische Portalschere eignet sich für verschiedene Alteisenverarbeitungsanlagen und kann Haushaltsabfälle, technische Abfälle, Abbruchabfälle, Winkelkanalstahl, Rohrleitungen und andere Altmetalle scheren. Der Betriebsmodus ist in die automatische und halbautomatische Fernbedienung unterteilt. Für Benutzer von Portalscheren ist es notwendig, den Klingenwechselvorgang und die sicheren Betriebsspezifikationen der Blechtafelschere zu verstehen. Das Folgende ist die entsprechende allgemeine Einführung.

Klingenmaterial einer hochbelastbaren Tafelschere aus Altmetall

Die Messer sind der Hauptteil des Schneidabschnitts der Portalschere. Die von unserem Unternehmen hergestellten Portalscherenmesser sind für den Einsatz an der Metallschere nach dem Abschrecken und Schmieden, der Materialmodulation, dem sekundären Abschrecken, der Materialprüfung und der Endbearbeitung von Werkzeugmaschinen ausgestattet. Die Klingenmaterialien werden hauptsächlich in H13, LD, SKD-11, D2, Cr12MoV, 6CrW2Si, 9CrSi, T8, T10 usw. unterteilt. Nach der Bearbeitung, dem Schleifen und der Wärmebehandlung kann die Härte dieser Art von Altmetall-Tafelschere HRC 50 erreichen -63. Der Preis von Klingen aus unterschiedlichen Materialien ist oft unterschiedlich, außerdem gibt es Unterschiede in der Scherleistung und den einsetzbaren Materialien.

Vorsichtsmaßnahmen für den Austausch von Schermessern

Nach der Auswahl des Messers muss das alte Messer der Portalschere ausgetauscht werden. Achten Sie beim Austausch auf die Einstellung des Klingenspalts, d. h. auf die Einstellung des Scheröffnungsspalts des beweglichen Messers und des feststehenden Messers. Stellen Sie bei der Einstellung zunächst den Abstand zwischen Ober- und Untermesser auf 0,5 mm ein und stellen Sie ihn dann von Anfang an mit einer Fühlerlehre ein, um den Abstand über die gesamte Länge des Messers grundsätzlich konstant zu halten. Anschließend stellen Sie die Klingenkante wieder auf Null Spielraum. Dann müssen Benutzer eine sorgfältige Anpassung vornehmen. Beobachten Sie während des Betriebs sorgfältig und lassen Sie die Ober- und Untermesser niemals beißen. Wenn sich bei der scharfen Klinge Grate an der Kante der Schnittplatte befinden, kann der Spalt zwischen Ober- und Untermesser entsprechend verringert werden. Durch die obige Einstellung können die Messer der Portalschermaschine ausgetauscht und der Spalt angemessen angepasst werden.

Wie bedient man die Altmetall-Tafelschere sicher?

Sicherer Betrieb der Altmetall-Tafelschere

- Schritt 1

Halten Sie sich strikt an die Sicherheitsvorschriften für Werkzeugmaschinenarbeiter und tragen Sie bei Bedarf Arbeitsschutzausrüstung.

Überprüfen Sie vor der Arbeit, ob alle Aspekte der Ausrüstung in Ordnung sind. - Schritt 2

Überprüfen Sie vor der Arbeit, ob alle Aspekte der Ausrüstung in Ordnung sind.

- Schritt 3

Die Beschickungsarbeiten nach dem Starten der Maschine müssen von Fachpersonal durchgeführt werden. Es ist strengstens verboten, Gegenstände aus hervorragenden Materialien in die Materialbox zu legen und Metalle aus hervorragenden Materialien wie Schienenstahl, Brecheisen, Hydraulikzylinder, ultradicke Eisenplatten oder vergüteten Stahl dürfen nicht geschnitten werden. Überschüssiges Stahlblech, hochwertiger legierter Stahl und andere Gegenstände, um Schäden an der Klinge zu vermeiden.

- Schritt 4

Nachdem das Gerät gestartet wurde, sollte es 1–2 Minuten lang im Leerlauf laufen und die obere Gleitplatte bewegt sich 2–3 Mal im Vollhub. Wenn ungewöhnliche Geräusche oder Fehler festgestellt werden, sollte das Gerät sofort gestoppt und der Fehler behoben werden. Erst wenn alles normal ist, kann der Betrieb wieder aufgenommen werden.

- Schritt 5

Die Arbeit sollte unter der einheitlichen Leitung einer Person erfolgen, so dass der Bediener und das Zufuhr- und Unterdrückungspersonal eng koordiniert sind. Arbeiter dürfen die Maschine während des Betriebs nicht verlassen.

- Schritt 6

Passen Sie je nach Dicke, Form und Größe des zu biegenden Blechs den Hub des Schiebers an und passen Sie die Auswahl der oberen und unteren Matrize sowie den Biegedruck an. Achten Sie bei der Auswahl der Größe des Untergesenks und der Überprüfung der Biegekraft des Werkstücks unbedingt auf die Biegekrafttabelle auf der rechten Seite der Werkzeugmaschine. Die Arbeitsbiegekraft darf nicht größer als die Nennkraft sein.

- Schritt 7

Wenn sich während des Betriebs herausstellt, dass das Werkstück oder die Form fehlerhaft ist, sollte dieser zur Korrektur angehalten werden. Es ist strengstens verboten, während des Betriebs manuelle Korrekturen vorzunehmen, um Handverletzungen vorzubeugen.

- Schritt 8

Schalten Sie den Strom sofort aus, wenn die Arbeit beendet ist.

Weitere Informationen zur Altmetall-Tafelschere finden Sie auf anderen Seiten der Website. Wenn Sie unsere Maschinen bestellen möchten, können Sie Ihre Daten auf der Website hinterlassen und wir stellen die Kontaktaufnahme mit unserem professionellen Verkaufspersonal her.