Semi-Automatic Horizontal Baler for Recycling

| Model | SL-120 |

| Dynamical system | hydraulic system |

| Power | 22kw, 3HP, 380V |

| Main Nominal thrust | 1200KN |

| System pressure | 28MPa |

| Control system | PLC automatic control |

| Feeding size | 1650mm*1100mm |

| Bale size | 1100*900mm |

| Bale density | 800Kg/Bale, 400-450kg/m³ |

| Capacity | 4-7 bales/h |

| Bundling | 3 pcs |

You can now ask our project managers for technical details

This horizontal baler from Shuliy Machinery is designed for waste paper, cartons, etc. It can quickly and effectively bale various materials, saving storage space and facilitating transportation. Every day, as production progresses, a large number of waste materials, such as paper, plastic, etc., are produced. How can they be processed quickly and effectively? So our hydraulic baler came into existence. The machine has very stable performance, excellent quality, and long service life. This machine is one of the most important recycling machines. If you are interested, please feel free to ask!

What is a horizontal baler?

A horizontal baler is designed to efficiently compress and pack various kinds of loose materials into dense packets convenient for storage and transportation. The hydraulic horizontal baler is characterized by a large compression ratio, compact package, neat and beautiful appearance, and wide application range. The horizontal waste baler is suitable for compressing and packaging various materials such as waste cartons, paperboards, paper, old clothing, plastics, tires, straw, forage, cotton, wool, sawdust, and woven bags. Moreover, our machines can be customized to meet all reasonable needs of our customers. Therefore, if you are in a related industry and need a baling machine, you are welcome to contact us at any time!

Automatic horizontal baler for sale

The automatic horizontal baling machine is a powerful and multifunctional machine for cotton-growing areas, textile enterprises, garment factories, waste material recycling stations, and other agricultural and industrial enterprises. The hydraulic baling press machine is mainly divided into horizontal and vertical types. The hydraulic horizontal baling press has a large shape, with a larger compression force and packaging size than the vertical metal baler, and it is easy to operate automatically, which can improve the overall efficiency of baling.

Semi-automatic horizontal baler machine

No automatic conveyor loading, need to find a way to put the waste material into the bin. Other functions remain the same.

Fully-automatic horizontal baling press

Equipped with an automatic loading machine, it can greatly save manpower and work quickly and efficiently.

Scope of application of the recycling baler machine

The horizontal baler machine is suitable for a wide range of recyclable materials and can be used with a conveyor and other equipment. Straw, hay, waste paper, tyres, cotton, old clothing, straw, plastic, wool, and recyclable rubbish can all be compressed and packed using a hydraulic baler. Waste cartons, waste paperboard, yarn, tobacco, cloth, woven bag, knitted velvet, sack, wool ball, silk, hops, and any other loose materials may also be utilized in it.

It is often used in packaging plants, carton plants, printing plants, waste classification and treatment stations, professional recycling stations, cotton-producing areas, textile enterprises, garment factories, and other places. The horizontal baler can cooperate with a threading machine for automatic baling.

Highlights of the automatic horizontal baler

The paper baling press has the advantages of high efficiency, compact structure, simple operation, stable transmission, flexible mobility, and others.

- Hydraulic technology, high pressure, energy saving, and environmental protection.

- The open structure makes it convenient and fast to take out the bag and improve efficiency.

- It adopts three side closing and reverses pulling type, which is automatically tightened and relaxed by the oil cylinder.

- PLC program, touch screen control, simple operation, automatic compression.

- The unique automatic baling device has the advantages of high speed, simple structure, stable action, low failure rate, and easy cleaning and maintenance.

- The package size and voltage can be customized according to the reasonable requirements of customers.

- It can be equipped with conveying line material and threading machine, with higher efficiency.

How does the horizontal waste baler work?

This series of horizontal baler is mainly composed of hydraulic system, material storage system, compression mechanism, bagging mechanism and electrical system. The production efficiency is 5-10 times higher than that of hydraulic vertical baler, and the power consumption is smaller. The hydraulic pressure can reach over 100 tons. The automatic horizontal baler machine includes full-automatic and semi-automatic types. The fully automatic model can be equipped with a threading machine to automatically bind the compressed package.

How much does a horizontal baler cost?

- The degree of automation. The price of a semi-automatic baler and a fully automatic baler is completely different because of the difference in the automatic loading system.

- Machine accessories. For the same machine, if use of different accessories, the price is also different. Of course, the service life and use conditions are not the same.

- Machine packaging and transportation. In the same conditions of transport, with no packaging and wooden box packaging, the total price of the machine is not the same. Similarly, if transporting the machine under the same packaging conditions, the price is also different.

Horizontal baler operating manual

- Before the machine starts to work, make sure to check whether each machine part is intact and whether the hydraulic oil is sufficient.

- When operating the machine, be sure to pay attention to personal safety, so the site must be adequate.

- When the machine is working, keep a certain safety distance. Because our machine adopts PLC control and can move forward in real-time, making good use of this.

- Safety first during the use of the machine. Constantly check the status and function of the safety interlock device and emergency stop device.

- After completing the work, check the machine when it stops completely to ensure that the machine is error-free before personnel leave.

Working video of horizontal baler

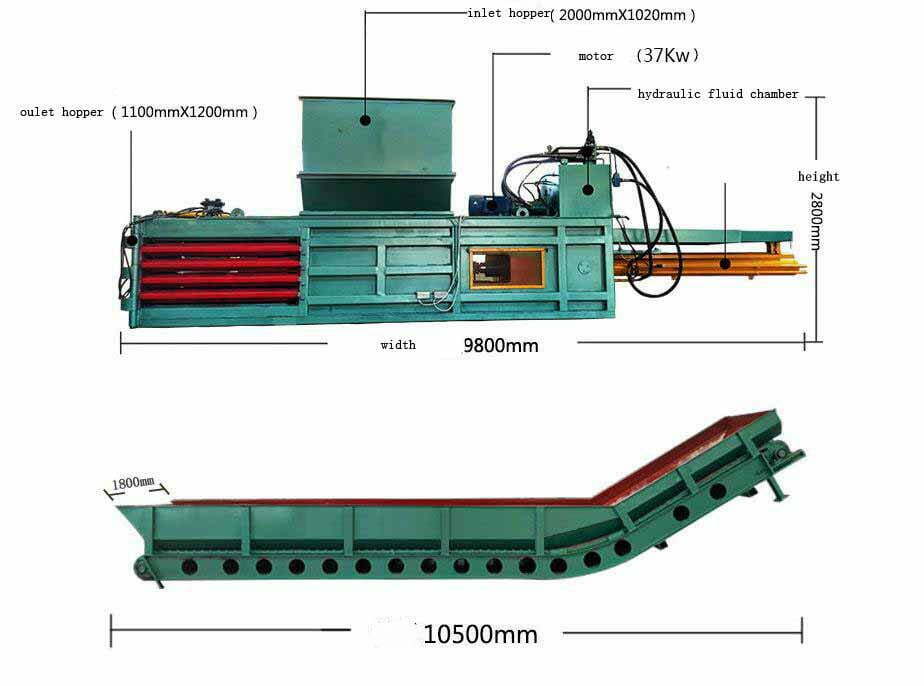

Specification of semi-automatic hydraulic horizontal baling machine

| Model | SL-120 | SL-160 | SL-180 | SL-200 |

| Dynamical system | hydraulic system | hydraulic system | hydraulic system | hydraulic system |

| Power | 22kw, 3HP, 380V | 30Kw+4Kw, 3HP, 380V | 37Kw+4Kw, 3HP, 380V | 45Kw+4Kw, 3HP, 380V |

| Main Nominal thrust | 1200KN | 1600KN | 1800KN | 2000KN |

| System pressure | 28MPa | 31.5MPA | 31.5MPa | 31.5MPa |

| Control system | PLC automatic control | PLC automatic control | PLC automatic control | PLC automatic control |

| Feeding size | 1650mm*1100mm | 1650mm*1100mm | 2000*1100mm | 2000mm*1100mm |

| Bale size | 1100*900mm | 1100mm*1250mm | 1100*1300mm | 1100mm*1400mm |

| Bale density | 800Kg/Bale, 400-450kg/m³ | 1200kg/Bale, 450kg/m³ | 1300kg/bale, 500kg/m³ | 1400Kg/Bale 520kg/m³ |

| Capacity | 4-7 bales/h | 5-8 bales/h | 6-9 bales/h | 8-10 bales/h |

| Bundling | 3 pcs | 4-5 pcs | 4-5 pcs | 4-5 pcs |

For more details about the baling machine or special requirements, welcome to get in touch with us.

FAQ

A: We can both manufacture and sell machines ourselves. We often export to foreign countries, which accounts for about 70%.

A: Generally, our company has a one-year warranty on our machines.

A: Our company has been a leader in the industry for decades. There are also industry certificates for you to check. In addition to that, we can also do a factory visit with you in real-time (via video).