Fully automatic CNC five-head rebar stirrup bending machine

Slab Bar Bending Machine | Stirrup Bender

Forming speed: 5 seconds

Processing capacity: 1500-2000m/hour

Angle error: ± 1°

Hydraulic pressure: 5-16Mpa

Air pressure: 0.4-0.6Mpa

Sizing method: manual/automatic

Machine power: 8kw

Machine weight: 1200kg

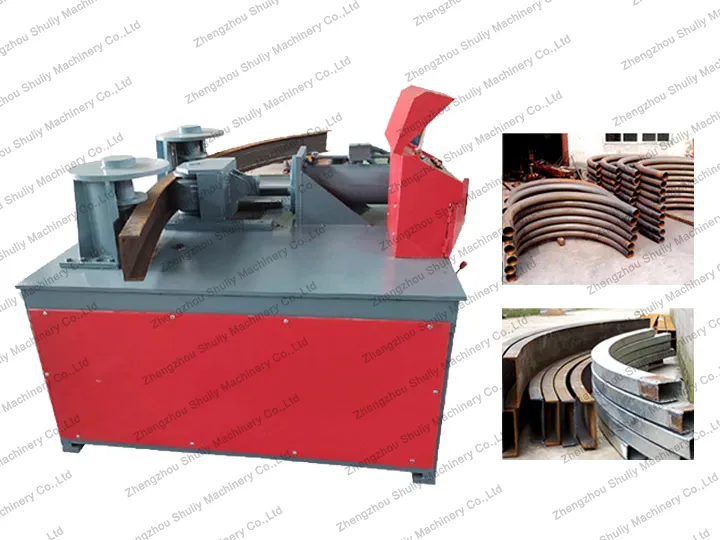

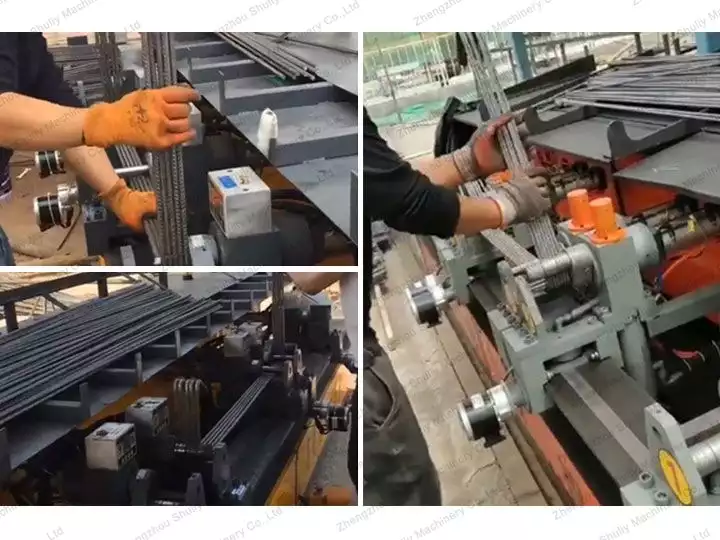

Shuliy rebar stirrup bending machine adopts the advanced 5-head design to bend steel bars of 1500-2000m per hour into desired shapes. It has a forming speed of 5 seconds.

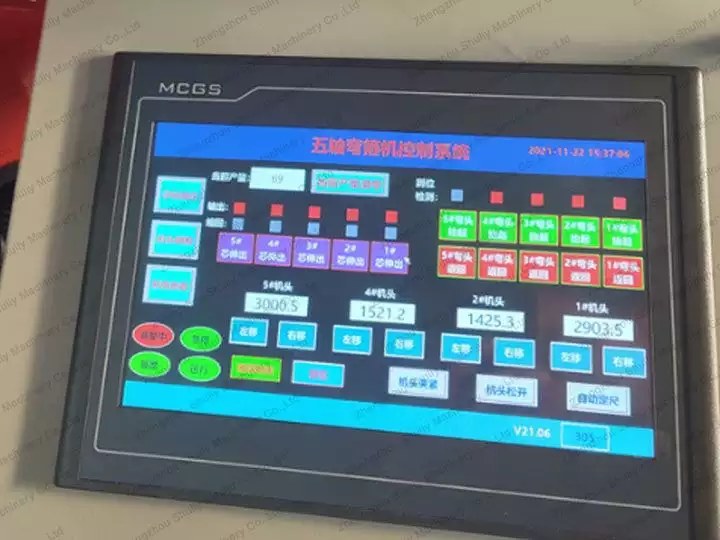

This slab bar bending machine has a CNC system that allows the reinforcing bar’s length and bending angle to set freely. The angle error is ± 1°.

Whether it is a construction site, a steel processing plant or a large-scale infrastructure project, this machine can provide efficient and precise solutions for rebar bending.

Advantages of automatic rebar stirrup bending machine

- 5-head design: this design can process many slab bars at the same time, significantly improving the production efficiency.

- CNC system:this advanced system can precisely control the size and angle of bending, ensuring the processing accuracy of each rebar.

- Adaption to various demands of steel bars: whether it is short or long rebar, the equipment can accurately handle to meet the processing requirements of different projects, and truly achieve “leave as long as possible, bend as long as possible”.

- Wide range of application scenarios: it’s widely used in construction sites, reinforcing steel processing plants and large infrastructure projects.

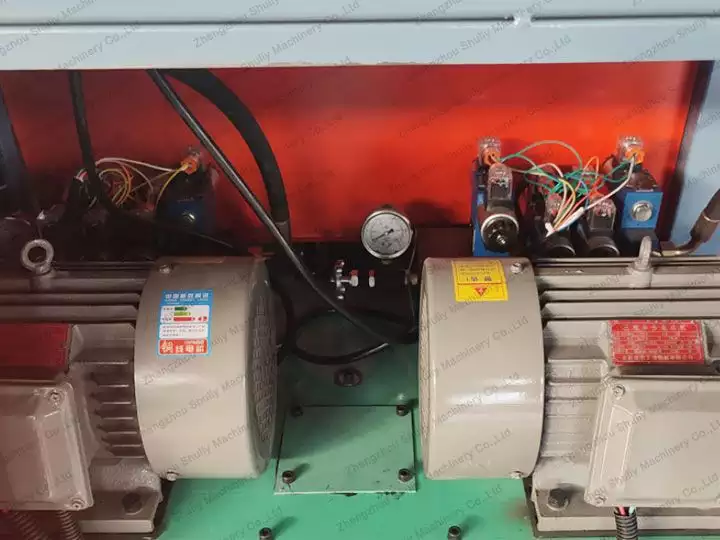

- Stability and durability: using two motors and made of high-strength materials, it can stably run for a long time, reduce maintenance costs and prolong service life.

Technical parameters of CNC rebar stirrup bending machine

The technical parameters of the CNC stirrup bender machine is an important reference basis for customers to choose equipment. From the below data, you can know its hydrualic pressure, forming speed, angel error, etc. For customers with special needs, we also provide customized parameter adjustment to meet different bending production needs.

- Hydraulic pressure: 5-16Mpa

- Sizing method: manual/automatic

- Machine power: 8kw

- Air pressure: 0.4-0.6Mpa

- Forming speed: 5 seconds

- Processing capacity: 1500-2000m/hour

- Machine head locking: hydraulic locking

- Angle error: ±1°

- Machine weight: 1200kg

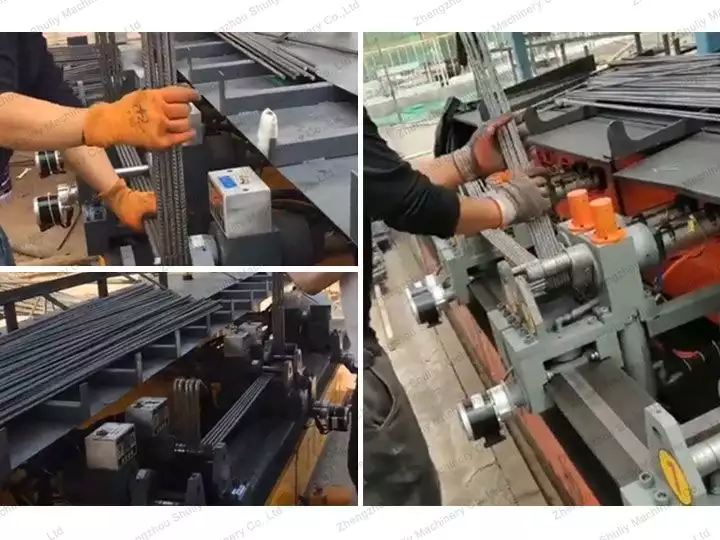

How does the slab bar bending machine work?

The working principle of the automatic CNC rebar stirrup bending machine is to set the bending angle, length and shape through the CNC system, automatic positioning, fixed length and locking to complete the steel molding. The working process is:

- Feeding: the steel bar enters the processing area through the feeding device.

- Positioning: the CNC system accurately locates the length and bending position of the rebar according to the preset parameters.

- Bending: the bending head completes the bending action according to the instruction to ensure that the angle and shape meet the requirements.

- Discharging: the finished steel bar needs to be taken out manually to prepare for the next round of processing.

What’s Shuliy rebar stirrup bending machine price?

The price of a CNC steel bar bending machine depends on a number of factors, including equipment materials, processing capacity, degree of automation and additional features. We offer a wide range of equipment sizes, from small, economical bending machines to high-performance, multifunctional CNC bending machines, at flexible price ranges.

Specific prices are based on the customer’s processing needs, order quantity and customization requirements. If you need a specific quote, you can contact us to recommend the most cost-effective machine for your production needs.

How to order one CNC stirrup bender from Shuliy?

Ordering a rebar stirrup bending machine is easy! The general process is:

- You can get in touch with us through online consultation, telephone or email, and tell us your processing needs.

- We will recommend the right model for you and provide you with detailed parameters, equipment pictures and videos to ensure you choose the most suitable equipment.

- After confirming the order, we will arrange rapid production, packaging and global shipment.

- When receiving the machine, we also provide installation guidance and after-sales service to ensure your smooth production.

Besides this equipment, we also have other rebar handling equipment, such as rebar straightening machine, rebar ring making machine, pipe bender and so on.

Welcome to contact us for a detailed quotation and technical support for your reinforcing bar processing!