CNC tube bending machine for copper steel pipes

CNC Pipe Bender | CNC Tube Coiling Machine

Bending range: 10-24mm, 20-51mm, 30-76mm, and 40-100mm

Angle range: 0-180 degrees

Suitable pipes: round pipes, square pipes, mandrel pipes, aluminum tubes, exhaust pipes, and others

Applications: aerospace, automobiles, motorcycles, ships, petrochemicals, natural gas, nuclear industry, fitness equipment, and so on

Shuliy CNC tube bending machine is mainly used to bend square or round steel pipes into the desired shape. The bending range is 10-100mm. The angle range is 0-180 degrees.

This equipment is especially suitable for large-volume, high-precision pipe processing, such as automotive manufacturing, furniture, fitness equipment and other industries, to improve production efficiency and reduce labor costs. Interested? If yes, come and contact us now for more information!

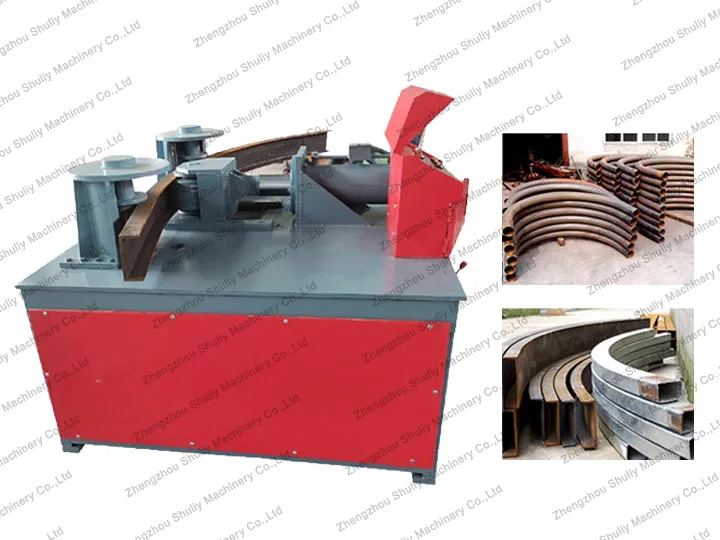

Finished products and applications of CNC tube bending machine

Our CNC square tube bending machine can bend various steel pipes into the desired shape. The end products are shown below for your reference.

The finished products are widely used in automobile & motorcycle manufacturing, aerospace, furniture manufacturing, fitness equipment, ships, petrochemicals, electric power, natural gas, nuclear industry, boilers, vehicles, air conditioning and refrigeration, sporting goods, building decoration, petrochemical and other industries.

Advantages of CNC pipe bender machine

- The CNC tube bending equipment has a bending range of 10-100mm and an angle range of 0-180mm, which makes steel pipes bend into various desired shapes.

- Our CNC pipe bending machine adopts a CNC system, ensuring precise bending of multiple angles and radii and reducing material waste.

- It uses an advanced hydraulic drive system, making the operation more stable and lower maintenance costs.

- Its end products have wide applications, such as aerospace, fitness equipment, ships, etc.

Technical parameters of CNC tube bending machine

Parameters of mandrel pipe bending machine

| Type | Model 38 | Model 51 | Model 76 | Model 100 |

| Bending range(mm) | 10-24 | 20-51 | 30-76 | 40-100 |

| Angle range(degrees) | 0-180 | 0-180 | 0-180 | 0-180 |

| Main speed(rpm) | 20 | 20 | 16 | 16 |

| Machine size(mm) | 800*650*900 | 850*700*930 | 940*780*960 | 1020*800*960 |

| Wall thickness requirement(mm) | 1-3 | 1-4 | 1-5 | 2-6 |

| Motor power | 3kw 4-pole (national standard) | 3kw 4-pole (national standard) | 4kw 6-pole (national standard) | 5.5kw 6-pole (national standard) |

| Input voltage | 3-phase 380V | 3-phase 380V | 3-phase 380V | 3-phase 380V |

| Machine weight(kg) | 230 | 260 | 290 | 360 |

Parameters of CNC pipe bending machine

| Type | Model-5 Hydraulic CNC | Model-9 Hydraulic CNC | Model-11 Hydraulic CNC |

| Steel bar diameter(mm) | 4-28 | 4-32 | 4-36 |

| Round tube diameter(mm) | 10-50 | 10-60 | 10-60 |

| Oval tube diameter(mm) | 30*80 | 30*80 | 30*80 |

| Machine weight(kg) | 700 | 900 | 1050 |

| Hydraulic motor power(kw) | 3 | 3.8 | 5.5 |

| Travel speed(m/min) | 12 | 12 | 12 |

| Travel motor(kw) | 4 | 4 | 4 |

| Overall dimension(mm) | 1100*1500*1200 | 1100*1800*1200 | 1100*1800*1200 |

How does the CNC tube bending machine work?

This CNC tube coiling machine accurately controls the pipe bending process through the CNC system to achieve high precision and high efficiency.

Firstly, the operator sets the bending angle, radius, bending speed and other parameters on the control panel.

Then, the feeding mechanism of the equipment feeds the pipe into the bending mold, the clamping system fixes the pipe, and the hydraulic drive device pushes the bending arm to bend at the set angle.

The whole process is accurately controlled by CNC program to ensure the consistency of each bending point and reduce errors and material waste.

How much does Shuliy CNC tube bending machine cost?

The price of CNC pipe bender is affected by a variety of factors, such as equipment model, processing capacity, control system, brand and additional features. Generally speaking, the price of basic CNC pipe bending machine is more economical, while the price of high-end configuration equipment is higher.

In order to get the most appropriate equipment quotes, we recommend that customers provide specific processing needs, so that we can recommend the best model for you.

How to choose the right CNC tube bending machine manufacturer?

Choosing the right CNC pipe bender manufacturer requires attention to several key factors.

- First of all, it is necessary to examine the professional experience and market reputation of the manufacturer. Choose the brand with many years of production experience and good customer feedback.

- Secondly, the quality and technical strength of the tube bending equipment are crucial. It is recommended to choose manufacturers with advanced production processes, strict quality control system, and provide high-precision, high-efficiency bending machine.

- In addition, after-sales service is also an important consideration. high-quality CNC tube bending machine manufacturers should be able to provide installation and commissioning guidance, operational training, maintenance and other comprehensive support.

- Finally, price and cost-effectiveness are equally important. It is recommended that a comprehensive comparison of different manufacturers of equipment performance, quality of parts, and offers. Choose the most suitable for the production needs of CNC pipe bender manufacturers.

For more information or quotation, welcome to contact us!

Contact us for a quote now!

If you’re interested in the CNC tube bender machine, welcome to contact us for more details! We also have other steel bar processing machines, such as steel bar straightener, rebar circle making machine, rebar stiirup bender, etc. No matter what you want to do with your rebar, we have a machine to suit your needs! Thus, if you have a demand, get in touch with us at any time!